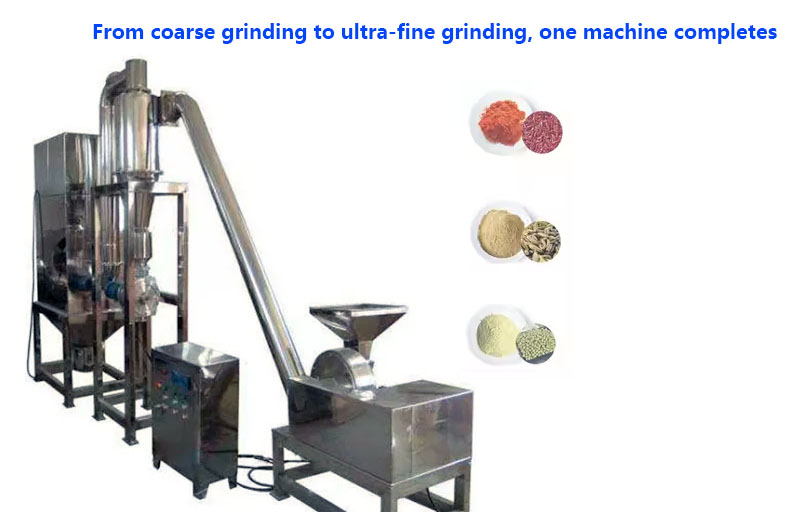

Micro-crushing machine

Equipment that can crush solid materials to micron or even nanometer levels

Grinding fineness: 0.5-0.015mm (conventional model), special model can reach 1-0.1μm

Feed particle size: ≤12mm (depending on the model)

Production capacity: from a few kg/h at laboratory level to 400kg/h at industrial level (VT-400 can reach 900kg/h)

Motor power: from 2.2kW small experimental machine to 22kW industrial model

What is a micro-crushing machine?

Micro-crushing machine is a high-efficiency equipment designed for ultra-fine crushing materials. It crushes materials to micron or even nanometer level through mechanical force. Compared with traditional crushing equipment, micro-crushing machine can achieve finer particle size control and is widely used in the production of powders that require high purity and uniform dispersion.

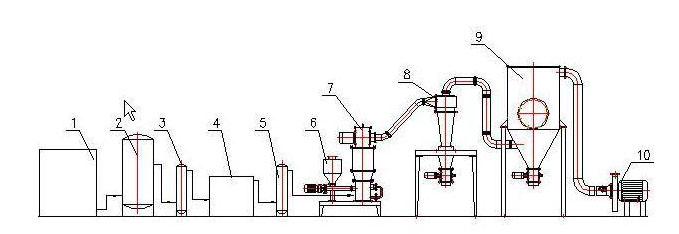

Our Micro-crushing machine adopts the outward-looking high-speed crushing principle. After the material enters the crushing chamber, it is crushed by a rotating hammer or blade to achieve an ideal crushing effect. The crushed material automatically enters the capture bag, and the dust is filtered and recovered by the dust collection box through the bag. There is no dust flying in the entire production process, which significantly improves material utilization and reduces corporate costs.

What types of Micro-crushing machines are there?

| Type | Applicable scenarios | Grinding fineness | Typical models | Features |

| Vibration type ultrafine pulverizer series | Material with strong fiber, high hardness, high sugar and high viscosity, such as: Chinese medicine wall breaking, spore powder processing | 1-0.1μm | LWF-6 to LWF-100 | Using vibration grinding technology, low temperature crushing, cell wall breaking rate 98% |

| High-speed impact micro-crusher series | Chemical, food, medicine | 10-1000μm | DCM-450, VT-300 | Crushing is achieved through high-speed relative movement between the movable disk and the fixed disk, and the product particle size distribution is narrow and spherical |

| Ceramic micro-powder machine series | Suitable for processing raw materials with high requirements for metal pollution, such as: electronic materials | 8-200μm | VT-300C | The material contact part is treated with zirconium oxide, silicon nitride or alumina ceramics, zero metal pollution, and full water washing design |

What are the advantages of Micro-crushing machine?

Ultrafine grinding ability: the output particle size can reach 0.5-0.015mm (500 mesh-5000 mesh), and can even reach the nanometer level of 1-0.1μm under special processes

High-efficiency cell wall breaking technology: the wall breaking rate of pollen and other spore materials is as high as 98%, effectively releasing active ingredients

Low-temperature operation: the lowest temperature of the refrigeration system can reach -45℃ to protect heat-sensitive materials

Fully enclosed design: in line with GMP standards, no dust pollution, no material loss

How does Micro-crushing machine work?

Different types of micro-crushing machines have different crushing principles, but their core goal is to overcome the cohesive force of the material by applying external force to crush it into fine particles. For example:

Airflow crusher: High-speed airflow accelerates the material and sprays it into the crushing chamber, and crushes it through mutual collision between materials and impact with the nozzle or target plate.

Mechanical impact crusher: The motor drives the rotor to rotate at high speed, and the hammer head, tooth plate or pin rod on the rotor impacts the material entering the crushing chamber at high speed to crush it.

Micro-crushing machine parameters

| Model | Main structural dimensions | Production capacity | Feed size | Discharge mesh | Spindle speed | Machine weight | Total power | ||||||

| L1 | L2 | H1 | H2 | H3 | H4 | W1 | Kg/H | mm | mesh | rpm | Kg | KW | |

| MR-15 | 3950 | - | 2640 | 850 | 650 | 350 | 1450 | 10-150 | 6 | 60-320 | 6000 | 1100 | 13.5 |

| MR-20 | 4300 | 5900 | 2800 | 850 | 650 | 350 | 1450 | 15-200 | 10 | 60-320 | 5400 | 1400 | 21 |

| MR-30 | 5250 | 7050 | 3200 | 950 | 650 | 350 | 1550 | 50-600 | 12 | 60-320 | 3800 | 2300 | 46 |

| MR-60 | 6100 | 8100 | 3700 | 1050 | 650 | 400 | 2000 | 100-1000 | 15 | 60-320 | 2900 | 3800 | 84 |

| MR-80 | 7200 | 9200 | 4250 | 1150 | 650 | 400 | 2300 | 120-1500 | 15 | 60-320 | 2500 | 5100 | 123 |

| MR-100 | 7900 | 10100 | 4500 | 1250 | 650 | 400 | 2500 | 150-2000 | 20 | 60-320 | 2000 | 7400 | 183 |

| Note: It can also be customized according to user needs | |||||||||||||

Micro-crushing machine industry solutions

Pharmaceutical and health care products industry

Modernization of traditional Chinese medicine: Solve the problem of crushing strong fiber medicinal materials such as Ganoderma lucidum and licorice, and high sugar and high viscosity medicinal materials such as jujube and wolfberry

Application of cell wall breaking: The spore powder wall breaking rate is more than 98%, and the supercritical extraction rate is increased from 10% to 17%, close to the theoretical oil content

Formulation reform: Realize new preparations such as raw powder soft capsules (such as ginseng soft capsules) and one-step pastes (such as Liuwei Dihuang soft capsules)

Improved clinical effect: After micronization, traditional prescriptions such as Bawei Dihuang Pills have reduced dosage and improved efficacy

Food and health care products

Functionality Food: Broken wall treatment of pine pollen, bee pollen, etc. to improve the absorption rate of nutrients

Seasoning processing: Ultrafine grinding of sugar and salt to improve solubility and taste

Special diet: Micronization of fiber in diabetic food to improve functionality and palatability

Chemicals and new materials

Powder coating: Ultrafine grinding of resin raw materials to improve coating uniformity and adhesion

Battery materials: Nano-scale grinding of electrode materials to improve battery performance

Polymer materials: Micronization of plastics, rubber and other raw materials to improve processing performance and finished product quality

Micro-crushing machine customer case

A pharmaceutical company uses LWF-25 micro-crushing machine to process Ganoderma lucidum, and the fiber crushing problem is solved, and the bioavailability of micro-powder slices is increased by 3 times

Food companies use VT-300C ceramic machine to process natural pigments, without metal pollution, and the products have successfully entered the high-end market of the European Union

Health care product factory spore powder wall breaking processing service, customer supercritical extraction rate increased from 10% to 17%, production cost reduced by 30%

How to choose a suitable Micro-crushing machine?

Material property analysis

Hardness: Mohs hardness classification, select equipment with corresponding impact energy

Fiber content: High-fiber materials are suitable for vibration grinding machines

Oil/sugar content: High-sugar and high-viscosity materials need to choose equipment with temperature control function

Thermal sensitivity: Materials that are easily decomposed by heat must choose models with refrigeration systems

Production demand assessment

Output requirements: From a few kg/h for small experimental machines to 500kg/h for industrial-grade equipment

Fineness standard: Clearly define the required particle size range (d50 value) and distribution requirements

Process matching: Consider the connection with the previous and subsequent processes, whether special interfaces are required

Sugested Products

Related news

Sieving Machine

Conveying equipment

Bucket Elevator

Mixer

Packaging Machine

E-mail:

sale@xxdahan.com

WhatsApp:

+86 15836198876

Add:

Yanjin county forest park gate to the west 1000 meters north road