Universal Crusher

Material: Carbon steel, stainless steel

Grinding fineness: 20-300 mesh

Production capacity: 10-5000kg/h (

Spindle speed: 1500-12000r/min

Motor power: 1.5-110kW

Feed particle size: ≤ 20-100mm

What is Universal Crusher?

Universal Crusher refers to equipment that can effectively crush a variety of materials of different properties. Unlike ordinary crushers that can only handle a specific hardness, moisture or fiber content, universal crushers usually use unique designs and adjustable components to enable them to adapt to a wider range of material types and crushing fineness requirements.

Why choose Universal Crusher?

Wide material adaptability: Our Universal Crusher can handle a variety of materials of different properties such as food (such as grains, beans, medicinal materials, seasonings, sugar, salt, etc.), chemical raw materials (such as resins, plastics, pigments, dyes, etc.), minerals (such as gypsum, talcum powder, limestone, etc.), feed, light industrial products, etc.

Adjustable particle size: By replacing screens with different apertures, the fineness adjustment of 10-1000 mesh (micron level) can be achieved.

Strong industry versatility: Applicable to multiple fields such as pharmaceuticals, food, chemicals, metallurgy, agriculture, etc.

Flexible structure: It can be equipped with modules such as water cooling, dust removal, ultra-low temperature crushing, etc. to meet different production needs

What types of Universal Crusher are there?

High-speed impact universal crusher: suitable for brittle materials such as Chinese herbal medicine and chemical raw materials.

Turbine universal crusher: suitable for fibrous materials (such as tea leaves and plant roots).

Ultra-low temperature universal crusher: uses liquid nitrogen cooling and is suitable for heat-sensitive materials (such as rubber and plastic).

Laboratory small universal crusher: suitable for small batch production such as scientific research and pharmaceutical research and development

What is the difference between Universal Crusher and ordinary crusher?

| Comparison items | Universal Crusher | Ordinary Crusher |

| Applicable materials | Hard, sticky, fibrous, and heat-sensitive materials can be processed | Only suitable for dry, low-hardness materials |

| Grinding fineness | 10-1000 mesh (can be ultra-finely crushed at micron level) | Usually only 20-120 mesh |

| Material standard | 304/316 stainless steel, in line with GMP requirements | Ordinary carbon steel or low-end stainless steel |

| Function expansion | Optional liquid nitrogen ultra-low temperature crushing, water cooling, dust removal system | Single function, no special configuration |

| Application industry | Medicine, food, chemical industry, new materials and other high-end fields | General agriculture, feed processing, etc. |

How does the Universal Crusher work?

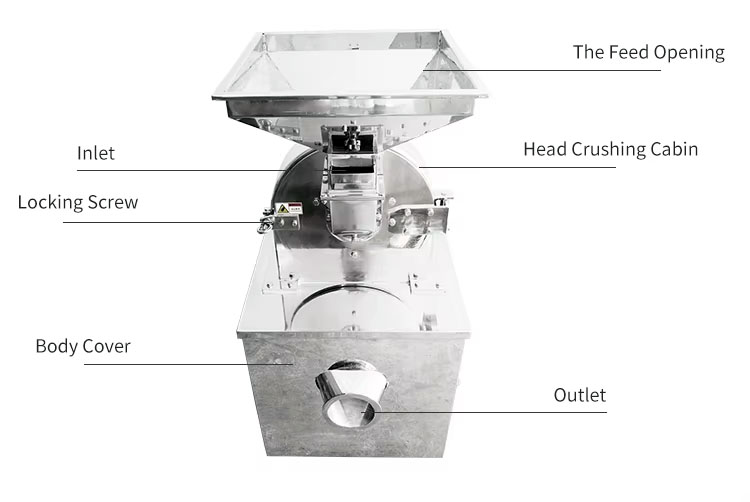

The Universal Crusher crushes materials through the impact, shearing and friction between the high-speed rotating dynamic disc and the fixed toothed disc. Specific process:

Feeding: The material enters the crushing chamber through the feed hopper.

Crushing: The high-speed hammer head/blade hits the material, and the materials rub against each other and crush.

Grading: Qualified fine powder is discharged through the screen, and the coarse material continues to circulate and crush 24.

Collection: The crushed material is collected by a cyclone separator or dust bag

Universal Crusher Technical Parameters

| Model | 20B | 30B | 40B | 60B |

| Capacity (kg/h) | 60-150 | 100-300 | 160-800 | 500-1500 |

| Motor power (kW) | 4 | 5.5 | 11 | 16.5 |

| Grinding fineness (mesh) | 60-120 | 60-120 | 60-120 | 60-120 |

| Noise (dB) | ≤85 | ≤85 | ≤85 | ≤85 |

| Material | 304 stainless steel | 304 stainless steel | 304 stainless steel | 304 stainless steel |

What are the applications of Universal Crusher?

Universal Crusher can be used in the food industry (crushing grains, beans, spices, chili powder, dehydrated vegetables, sugar, salt, biscuits, feed, etc.), the pharmaceutical industry (crushing Chinese herbal medicines and Western medicine raw materials), the chemical industry (ultra-fine crushing of plastics, rubber, pigments), agriculture & feed (crushing corn, soybean meal, feed raw materials), etc.

Universal Crusher Customer Case

A chili powder manufacturer in China needed a crushing machine that meets FDA standards. The requirements were:

No pollution: 304 stainless steel, easy to clean.

Controllable fineness: 80-100 mesh uniform crushing.

Low-temperature crushing: avoid volatilization of capsaicin.

Solution: Use a water-cooled universal crusher, control the temperature ≤40℃; equipped with a cyclone dust removal system to reduce dust spillage.

Result: Production capacity increased by 40%, product fineness is uniform, and there is no agglomeration.

How to choose the right Universal Crusher?

Material characteristics: brittleness, fibrousness, heat sensitivity?

Capacity requirements: small test, pilot test or large-scale production?

Fineness requirements: Is ultra-fine grinding (<1000 mesh) required?

Industry standards: Is GMP/FDA certification required?

Special requirements: Is low temperature, explosion-proof, and anti-oxidation function required?

Sugested Products

Related news

Sieving Machine

Conveying equipment

Bucket Elevator

Mixer

Packaging Machine

E-mail:

sale@xxdahan.com

WhatsApp:

+86 15836198876

Add:

Yanjin county forest park gate to the west 1000 meters north road

Micro-crushing machine

Micro-crushing machine Coarse crusher

Coarse crusher