Particle Size Test

Particle Size Testing Laboratory Sieve is priced between $20.00 and $3,000.00 per set.There are various models available, typically classified by type (such as ultrasonic, electromagnetic, electric) and sieve mesh specifications (for example 20-200 mesh, 200-1000 mesh).

Diameter:500/400/300/200/120/80/75mm

frame layers: 1-8 layers

Feeding amount:200g

Measuring range: 20µm-125mm

Voltage: 220V

Dimensions:360*300*736

What is Particle Size Test?

Particle Size Test is a crucial process used to measure and analyze the dimensions of particles in granular materials. For industries that rely on precise particle separation, such as pharmaceuticals, chemicals, and mining, understanding particle size testing is essential for ensuring product quality, process efficiency, and compliance with industry standards. Below, we will answer some key questions to help you understand this important technology.

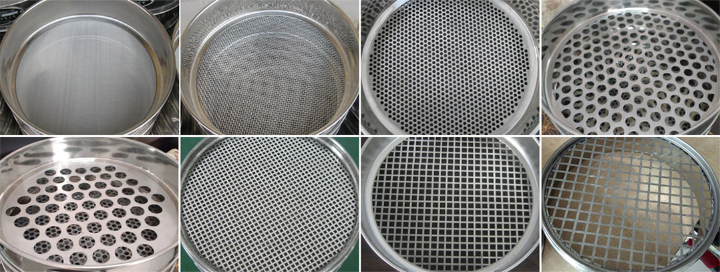

What are the common types of test sieves for particle size test?

These test sieves are specialized equipment for particle size test, each with unique vibration modes and applicable particle ranges to meet diverse testing needs.

Ultrasonic Test Sieve: Equipped with an ultrasonic generator, it uses high-frequency vibrations (20-40kHz) to prevent fine particles (≤50μm) from clogging the sieve mesh. Suitable for testing ultra-fine powders such as pharmaceutical APIs, toner, and nanomaterials, it improves screening efficiency by 30-50% compared to conventional sieves and ensures accurate results for particles in the 5μm-500μm range.

Electromagnetic Test Sieve: Driven by electromagnetic vibration, it features adjustable amplitude (0-2mm) and frequency (50-300Hz) for precise control. Ideal for high-precision testing of medium-sized particles (50μm-2mm) like metal powders and ceramic granules, it offers stable vibration performance with minimal noise, meeting laboratory accuracy requirements.

Electric Test Sieve: Powered by a motor, it generates circular or linear vibrations to sieve particles through multi-layer meshes (20-500 mesh). Suitable for routine particle size analysis of coarse to medium powders (100μm-5mm) such as ores, food grains, and construction materials. It supports batch testing with adjustable working time, balancing efficiency and simplicity for industrial quality control.

What is the method of Particle Size Test?

Preparation Work: Select a set of laboratory sieves with different mesh sizes that meet the standards. Prepare the sample to be tested, a screening machine (such as a vibratory or tapping type), and a balance.

Operation Process: Stack the laboratory sieves in descending order of mesh size. Place a fixed amount of the sample on the top - most sieve. Start the screening machine and set appropriate vibration time, frequency, and amplitude for screening.

Result Acquisition: After the screening is completed, weigh the mass of the particles retained on each sieve. Calculate the proportion of particles in different particle - size intervals to obtain the particle - size distribution results.

Presentation of Particle Size Distribution Results

| Size | Weight | P3 | Number | P0 |

| 5 mm | 190 g | 25 % | 490 | 85,5 % |

| 10 mm | 190 g | 25 % | 64 | 11,2 % |

| 15 mm | 190 g | 25 % | 18 | 3,1 % |

| 40 mm | 190 g | 25 % | 1 | 0,2 % |

| Total | 760 g | 100 % | 573 | 100 % |

Parameter

| tems | Name | Unit | Data |

| 1 | Layers | layer | 1-8 |

| 2 | Diameter | mm | 200, 300 |

| 3 | Sieve frame | mm | 100, 200, 300, 400 |

| 4 | Noise | db | below 50 |

| 5 | Feeding Capacity (Once) | g | <200 g/ml |

| 6 | Amplitude | mm | <5 |

| 7 | Voltage | v | 220 v / customized |

| 8 | Power | kw | 0.125 |

| 9 | Overall Dimension | mm | 450*410*700 |

| 10 | Weight | kg | 60 |

Why is Particle Size Test Vital for Production?

The size of particles directly determines the performance and application effectiveness of materials. Accurate testing offers three core benefits,including Guaranteed Product Quality,Enhanced Production Efficiency and Compliance with Industry Standards.

Guaranteed Product Quality: Ensures that critical indicators such as the dissolution rate of pharmaceuticals, conductivity of battery materials, and fineness of coatings meet the required standards.

Enhanced Production Efficiency: Prevents screen blockages and equipment wear, reduces raw material waste, and cuts down on rework costs.

Compliance with Industry Standards: Meets strict domestic and international particle size control regulations, such as those set by the FDA (for pharmaceuticals) and ASTM (for materials).

What are the Applications of Particle Size Test?

From traditional manufacturing to cutting-edge technologies, six major sectors highly depend on particle size test.

Pharmaceutical Industry: Controls the fineness of drug particles to ensure drug efficacy and absorption (e.g., inhalants and dispersible tablets).

New Energy Sector: Tests the particle size distribution of anode and cathode materials in batteries (such as lithium iron phosphate and silicon-carbon anodes) to improve battery cycle life.

Chemical and Coating Industry: Optimizes the uniformity of pigment and filler particles to ensure the gloss and adhesion of coatings.

Food and Cosmetics Industry: Controls the texture of flour, emulsions, etc., to enhance taste and user experience.

Mining and Construction Materials Industry: Screens the particle size of ores and aggregates to improve resource utilization and the strength of concrete.

Nanomaterial Field: Precisely measures the size of nanoscale particles like graphene and titanium dioxide, unlocking their optoelectronic and catalytic properties.

Although the particle size test seems simple, it is a key bridge connecting the microscopic characteristics of particles and macroscopic applications. From laboratory research and development to industrial mass production, its value lies not only in providing a set of particle size data, but also in helping to optimize process parameters, improve product performance, and reduce quality risks through precise particle grading. With the refined development of materials science and manufacturing, experimental screening technology will continue to iterate, and continue to empower the precise control of the granular world in a smarter and more efficient way.