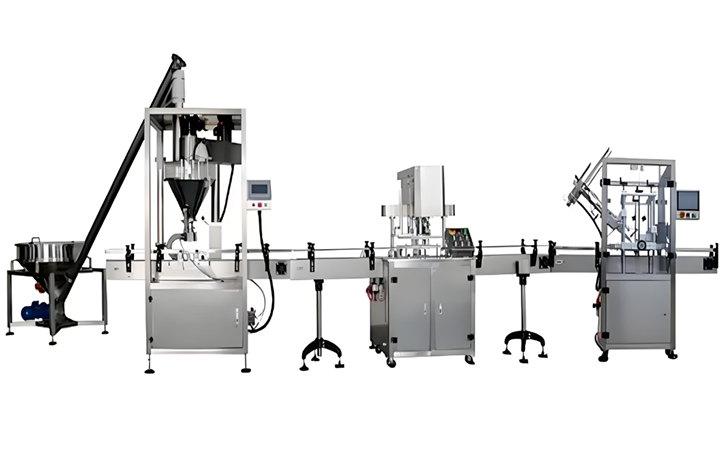

Fully automatic pharmaceutical packaging machine production line

Tuesday December-02 2025 11:15:57

Fully automatic pharmaceutical packaging machine production line consists of multiple interconnected devices, commonly including bottle unscramblers, capping machines, labeling machines, automatic checkweighers, packing machines, and end-of-line palletizers. Depending on the type of medicine, such as tablets, capsules, or injections, blister packing machines, aluminum-plastic packaging machines, tablet counters, and powder filling machines can also be added. By changing the molds and adjusting the parameters, it can accommodate medicines of different specifications.

The fully automatic pharmaceutical packaging machine consists of a lifting and conveying system, a metering device, a bag-making system, a filling unit, a sealing device, a coding system, and a finished product output device. Bag-making accuracy is controlled within ±1mm, and sealing temperature deviation does not exceed ±1℃. Depending on the configuration, production speed can reach 20-80 bags per minute or even higher. The system is available in single-head, multi-head, and weighing types. A PLC intelligent control system coordinates each step of the production line, automatically completing the lifting, weighing, filling, sealing, and coding processes for ointments, liquids, and other materials.

Fully automatic pharmaceutical packaging machine production line process

Fully automated equipment in a fully automatic pharmaceutical packaging machine production line is central to ensuring efficiency and compliance. Typical fully automated tablet, capsule, and bottle counting, filling, capping, and labeling lines are the cornerstone of solid dosage form packaging. Combinations of equipment such as bucket elevators, belt conveyors, inclined screw conveyors, chain conveyors, and turning conveyors can be selected. The entire production line process begins with material conveying: granular materials are conveyed using bucket elevators or Z-type elevators, while less free-flowing powdery materials are preferably conveyed using inclined screw conveyors. After being lifted to the storage hopper, the material is weighed by high-precision counting or multi-head electronic scales. Subsequently, the material enters the fully automated filling and sealing line to complete filling, capping, and labeling. Similar integrated systems are also used in dynamic soft capsule production lines and packaging for other dosage forms. The packaging machine automatically completes bag making and drug filling, and uses processes such as heat sealing to achieve sealing and prevent contamination. Finally, an inkjet printer prints the information and outputs the finished product. This integrated system ensures that the entire process is fully automated, dust-free, and requires no human intervention, meeting GMP standards.

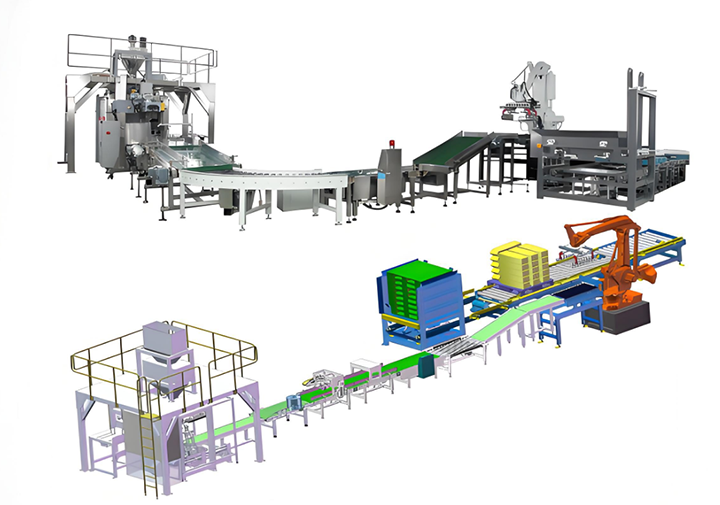

Fully automatic pharmaceutical packaging machine production line solution

Fully automatic pharmaceutical packaging machine production line solutions are designed to meet the packaging needs of powders, tablets, liquids, capsules, and other pharmaceuticals. The equipment uses either a pre-made or bag-making packaging machine, compatible with various bag types such as aluminum-plastic bags and composite film bags, and can achieve different sealing methods including back seal, three-side seal, stand-up pouches, and flat bags. The production line integrates automatic feeding, counting and filling, desiccant dispensing, vacuum/nitrogen filling, heat sealing detection, and finished product output, forming a continuous closed-loop production. For pharmaceuticals requiring protection from light and moisture, a vacuum system can be equipped, with residual oxygen levels controlled below 1%. The standard line speed can reach 80-120 bags/minute, with a daily output exceeding 100,000 bags. A PLC and vision inspection system ensures that the packaging seals and label clarity meet GMP standards.

What are the application areas of Fully automatic pharmaceutical packaging machine production line?

In the production of solid preparations, the tablet packaging line integrates a fully automatic tablet packaging machine, which supports three-side or four-side sealing packaging of solid medicines such as sugar-coated tablets, plain tablets, and capsules, with excellent moisture-proof and light-proof properties; in the modern packaging of traditional Chinese medicine, for large honeyed pills such as Liuwei Dihuang Pills, a gravity slide cartoning machine with a pill counting sensor is used to replace the traditional wax shell packaging, solving the adhesion problem; in clinical trial drugs, the modular cartoning machine can handle small batches of 5-500 boxes by quickly changing molds, and supports personalized instruction manual folding and serial number coding; for sterile product packaging, some models integrate a weight detection module, which can automatically reject missing or insufficient ampoules to ensure the compliance of liquid preparation packaging.

Fully automatic pharmaceutical packaging machine production line applicable materials

Fully automatic pharmaceutical packaging machine production line is applicable to two major types of materials: granular and powder. The equipment has different packaging forms and processing issues when handling two different materials.

Granular drugs usually use a drop-type weighing and automatic filling system. The bag types are mostly back-sealed bags, three-side sealed bags or four-side sealed bags. Some models support customized packaging such as self-supporting bags and corner-inserted bags. This system is suitable for the packaging of irregular particles such as cold granules, vitamin tablet granules, and granules. In the modern packaging of traditional medicinal materials such as wolfberry and Panax notoginseng powder, the secondary compaction process of the inserting mechanism effectively solves the problem of filling volume differences caused by material sedimentation. The core of granular packaging is to solve the density problem of fluffy materials.

Powdered drugs use a spiral metering and filling system to avoid powder flying and ensure metering accuracy. In terms of bag types, pillow bags, sealed flat bags or three-side sealed bags with easy-tear edges are commonly used. Some models also support multi-layer materials such as aluminum foil bags and composite film bags to ensure the requirements of light-proof, moisture-proof and oxidation-proof drugs. This system is suitable for the packaging of different powder materials such as medicinal protein powder, medicinal powder, and Chinese medicine powder. The focus of powder packaging is dust prevention and sealing.

Fully automatic pharmaceutical packaging machine manufacturer

In the fully automated pharmaceutical packaging machine production line, some manufacturers focus on bottled pharmaceutical production lines, while others specialize in powdered pharmaceutical production lines. Machrise provides equipment for the entire pharmaceutical packaging process, including material hoists such as vertical vibrating elevators and NE plate chain bucket elevators, screw conveyors such as mobile screw conveyors, pharmaceutical packaging machines including granule and powder packaging equipment, and finished product conveyors such as belt conveyors. This equipment is highly automated, enabling self-diagnosis of faults, data tracking, and production management. Through various combinations with fully automated pharmaceutical packaging machines, it can support multi-specification and multi-batch production. Furthermore, it reduces manual intervention, automating processes such as pharmaceutical feeding and packaging.

The fully automatic pharmaceutical packaging machine production line, with its modular design, highly automated control system, and diverse packaging formats, has become a crucial piece of equipment for pharmaceutical companies to achieve large-scale, standardized production. This equipment effectively addresses density issues for granular pharmaceuticals and dust and sealing issues for powdered pharmaceuticals. Whether granular or powdered, it enables fast, accurate, and pollution-free automated packaging, effectively improving production efficiency and product competitiveness.