Fully automatic chemical packaging machine price

Friday September-19 2025 16:17:23

Fully automatic chemical packaging machine price varies significantly depending on the configuration, ranging from US$3,000 to US$20,000. They are the preferred choice for many chemical companies seeking to improve automation and packaging efficiency.

This equipment provides fast and precise packaging for the chemical industry. Its structure integrates mechanical, electrical, and automated control technologies, completing the entire process from material metering, filling, to sealing. Typical machine specifications include a packaging speed of 5-600 bags/minute, a metering accuracy of ±0.2%-2%, and compatibility with valve bags, pre-made bags, and ton bags, with a weight range of 25kg to 1000kg per bag.

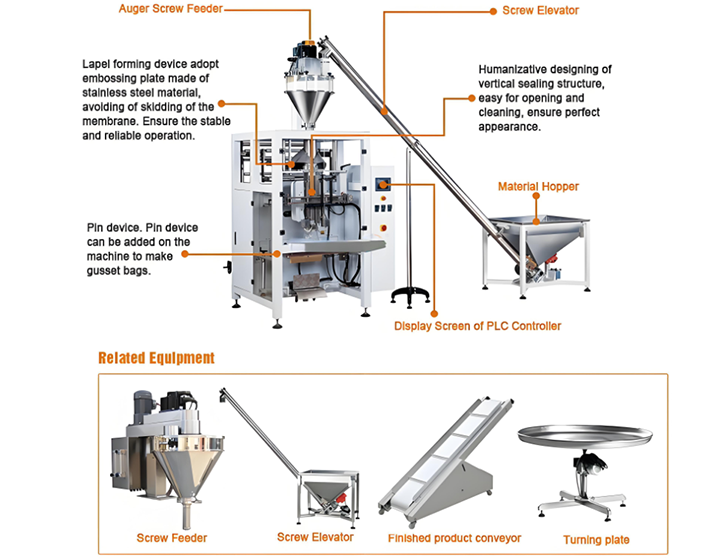

Core components of Fully automatic chemical packaging machine

Fully automatic chemical packaging machine is mainly composed of five parts: metering system, bag making and filling system, sealing system, control system, conveying and output,Fully automatic chemical packaging machine price is related to the parts.

The metering system uses spiral feeding, vibration feeding or vacuum suction technology, combined with high-precision weighing sensors to achieve dynamic metering with an error of ≤±0.5%; the bag-making and filling system automatically makes bags through roll film or docks pre-made bags, combined with spiral, drop or vibration filling methods to achieve rapid filling; the sealing system adopts heat sealing or cold sealing, which provides a firm and beautiful seal and is suitable for packaging films of different materials; the control system is equipped with a PLC+touch screen interface, which is easy to operate, can store multiple recipes, and supports automatic alarm, self-test and other intelligent functions; the finished packaged bags are automatically transported to the coding, inspection or packaging station to realize the linkage of the packaging line.

Fully automatic chemical packaging machine price range

Fully automatic chemical packaging machine price range is relatively wide, depends primarily on its technical specifications and the complexity of the application scenario. Entry-level machines typically have a basic configuration and are suitable for small and medium-sized enterprises or users with low production capacity requirements. They are commonly used to package single materials such as PVC powder and calcium carbonate, and their prices range from US$2,000 to US$5,000. Mid-range models feature a higher degree of automation, equipped with a variety of sensors and intelligent control systems. They can accommodate a variety of bag types, such as pillow bags, gusset bags, and four-side seal bags. They are suitable for medium-sized chemical production lines, and fully automatic chemical packaging machines cost between US$5,000 and US$9,000. High-end customized models support multi-station operation, remote monitoring, corrosion-resistant stainless steel construction, and even include automatic feeding, weighing, and dust removal systems. They are widely used in large-scale continuous production plants, and their prices generally range from US$11,000 to US$20,000. Different users can choose the most suitable equipment model based on their budget, material characteristics, and production requirements.

Fully automatic chemical packaging machine Applicable material types

Fully automatic chemical packaging machine is suitable for conventional powders, corrosive materials, liquids and pastes and high-risk chemicals, etc. When handling high-risk chemicals, explosion-proof motors and other equipment are required, so Fully automatic chemical packaging machine price will be different.

Conventional powders: resin particles, fertilizers, food additives, talcum powder, PVC powder, flour, milk powder, coffee powder, feed premixes, etc. The equipment material is required to be 304 stainless steel or carbon steel spray.

Corrosive materials: phenol, formaldehyde, hydrochloric acid, nitric acid, phosphoric acid, ammonium chloride, calcium chloride, sodium hypochlorite, hydrofluoric acid, potassium hydroxide, ammonia, copper sulfate, etc. 316L stainless steel or Teflon coating is required, and fluororubber is used for seals.

Liquids and pastes: disinfectants, glue, emulsion, motor oil, resin slurry, silicone oil, liquid fertilizer, glycerin, etc. Low-viscosity liquids such as disinfectants are measured by flow meters, while high-viscosity materials (such as asphalt) require screw pumps.

High-risk chemicals: Applicable materials include liquefied petroleum gas, vinyl chloride, aluminum powder, magnesium powder, nitrocellulose, peroxides, silicone catalysts, etc. Explosion-proof motors, gas monitoring and emergency eyewash devices are required to comply with ATEX or NEMA standards.

Fully automatic chemical packaging machine online manufacturer

Our 10,000-square-meter factory serves over 80 countries. As a leading manufacturer, Fully automatic chemical packaging machine price we produce meets the needs of many companies, eliminating middlemen and offering trial runs with materials. If you're unsure about the model, our professional engineers can customize it based on factors like production volume, space requirements, and price. This has earned us the trust of numerous partners.

Fully automatic chemical packaging machine, depending on the function and configuration, the price of the whole machine ranges from US$3,000 to US$30,000; in terms of application, the equipment is widely used in a variety of chemical materials such as powder, granular, and crystalline, covering coatings, plastics, additives, new materials and other industries. For companies that pursue automated production, save labor costs, and improve packaging consistency, this equipment is an ideal choice for upgrading production lines. When purchasing, it is recommended to combine your own material characteristics and packaging requirements, and choose a professional manufacturer with customization capabilities and service guarantees to ensure long-term and stable operation of the equipment.