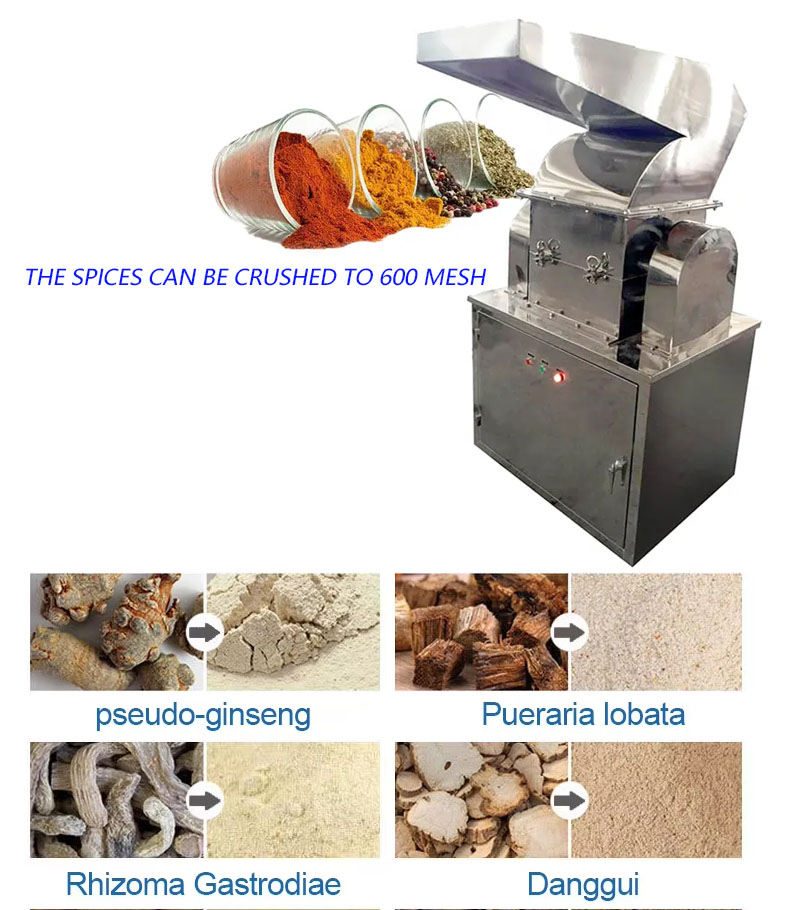

Spices Coarse Crusher

It is a coarse crusher used to crush various spices in granular, lumpy, and irregular shapes. The price ranges from $230 to $5,800.

Fineness range: 10-600 mesh

Output: 50-3000 kg/h

Feed particle size: ≤2cm

Applicable spices: pepper, chili, star anise, Sichuan pepper, Sichuan pepper, cloves, ginger powder, garlic powder, cinnamon.

What is Spices Coarse Crusher?

Spices Coarse Crusher is designed to crush various granular, lumpy, and irregularly shaped spices into a powder of a specific particle size, ensuring uniform particle size and maintaining a well-balanced flavor. It can also handle a wide range of spices up to 600 mesh, with a production capacity of up to 3,000 kg. From feeding to discharging, the entire process is highly automated, reducing manual intervention and labor intensity while ensuring hygienic and pure spice crushing. Whether it's hard spices like star anise and cinnamon, oily spices like Sichuan peppercorns and peppercorns, or heat-sensitive spices like ginger and garlic, we have specialized solutions.

What types of Spices Coarse Crusher are there?

Spices Coarse Crusher is divided into three models: turbine type, low-temperature liquid nitrogen type, and ultra-micro type. You can choose according to the properties of the crushed spices (such as granular, lumpy, irregular, etc.) and the crushing needs.

Turbine Spices Coarse Crusher: Suitable for most conventional spices (star anise, cinnamon, pepper, etc.), using a high-speed rotating turbine and a screen grinding block, the fineness is adjustable from 30-150 mesh, and the output is 40-800kg/h2.

Low-temperature liquid nitrogen Spices Coarse Crusher: Designed for heat-sensitive spices (such as ginger, garlic, chili, etc.), using -196℃ liquid nitrogen cooling and crushing to maintain the original flavor and active ingredients of the spices, the fineness is adjustable from 10-600μm3.

Ultra-fine Spices Coarse Crusher: Used for high-end spice powders (such as matcha powder, vanilla powder, etc.), using the stone mill principle for low-temperature crushing, the minimum particle size can reach 20μm, and does not change the flavor of the food

What are the advantages of Spices Coarse Crusher?

Spices Coarse Crusher uses advanced crushing technology to ensure that the spices are uniform in particles and retain their flavor after crushing, and adapt to the processing needs of different spices.

Precise crushing: With an adjustable screen system, the crushing fineness can be precisely controlled within the range of 10-150 mesh (600-100μm) to meet the needs of different spices.

Efficient production: The maximum output can reach 3000kg/h (depending on the model), which greatly improves production efficiency and reduces unit energy consumption.

Wide adaptability: It can handle various spices such as high oil (pepper), high fiber (cinnamon), and sticky (ginger powder)

Low temperature protection: Optional liquid nitrogen cooling to prevent the flavor of heat-sensitive spices (such as pepper and cloves) from volatilizing.

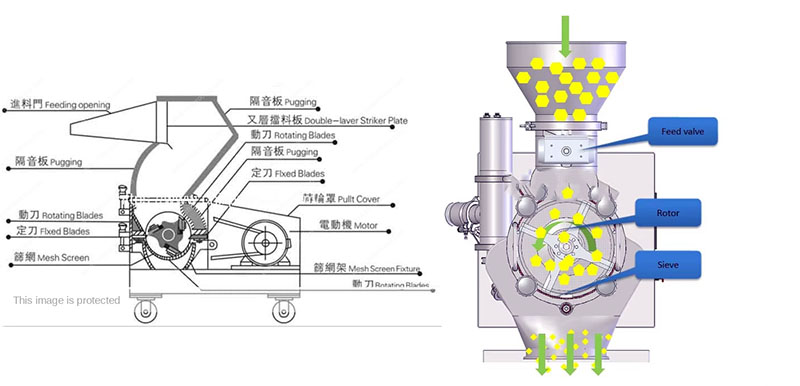

How does Spices Coarse Crusher work?

The working principle of Spices Coarse Crusher is based on high-speed mechanical force and precise grading design to achieve efficient crushing of spices. After the material enters the crushing chamber through the feeding hopper, the high-speed rotating knife disc and the fixed grinding block form a strong impact and friction field, so that the spice particles are continuously refined under the action of centrifugal force and mechanical force. During this process, particles that meet the preset fineness are separated through the screen and enter the aggregate bag, while coarse particles that do not meet the standard continue to be impacted and ground in the cavity, forming a circulating crushing mechanism. In order to prevent the aroma of spices from volatilizing or the deterioration of ingredients due to frictional heat, some models are equipped with air cooling or liquid nitrogen cooling systems to control the crushing temperature in a low-temperature environment to ensure the stability of the spice quality. The entire process coordinates the feeding, crushing, grading and cooling links through an automated control system to achieve precise conversion from coarse materials to fine powder.

Spices Coarse Crusher Technical Parameters

| Parameter category | Conventional model | Low temperature model | Ultra-fine model |

| Grinding fineness | 10-150 mesh | 10-600μm | 20-1000 mesh |

| Feed size | ≤6-10mm | ≤2cm | ≤5mm |

| Production range | 30-1600kg/h | 1-1000kg/h | 5-90kg/h |

| Motor power | 4-22kW | 16.5-65.5kW | Special design |

| Spindle speed | 2900-4500r/min | Frequency control | Low speed design |

| Cooling method | Air cooling/water cooling | Liquid nitrogen (-196℃) | Low temperature grinding |

| Material standard | Stainless steel 304 | Stainless steel 316 | Food grade ceramics |

What are the applications of Spices Coarse Crusher?

Spices Coarse Crusher has been efficiently applied in the production lines of many well-known brands and manufacturers: the turbine crushing solution customized for large-scale condiment factories can process 800kg of raw materials per hour for hard spices such as star anise and cinnamon, with a crushing fineness of 40-80 mesh, accurately meeting the large-scale production needs of five-spice powder; for oily spices such as prickly ash and pepper, a special anti-stick design model is used to effectively solve the adhesion problem during the crushing process and achieve a stable output of 300kg/h; in the production of ginger and garlic powder, a -196℃ low-temperature crushing system is used to ensure that the active ingredients and flavor of ginger and garlic are fully preserved, and the crushing fineness is controlled at 100-200 mesh; for products with strict requirements on particle size such as high-end matcha powder, the particle size is refined to 20μm through ultra-fine crushing technology, perfectly maintaining the color and taste of the raw materials; and the multi-functional crushing unit is good at processing composite spice powder, which can mix and crush multiple spices at the same time, with an hourly output of 1200kg and material uniformity exceeding 100%. 95%, fully meeting the refined needs of various complex production scenarios.

Spices Coarse Crusher Customer Story

| Application Scenario | Crushed Material | Feed Particle Size | Discharge Particle Size | Production Volume | Remarks |

| A Food Processing Plant in Southeast Asia (Seasoning Production) | Dried Chili Peppers, Star Anise, Cinnamon | ≤50mm | 2-5mm | 300kg/h | Stainless steel, dust-proof design |

| A Chinese herbal medicine processing company | Cinnamon, cloves, and tsaoko | ≤30mm | 1-3mm | 200kg/h | Equipped with a cyclone separator to reduce fine dust emissions |

| A European spice export trading company | Pepper, cumin, and fennel | ≤20mm | 0.5-2mm | 500kg/h | Variable frequency speed regulation to adapt to different material hardness requirements |

How to choose Spices Coarse Crusher?

Choose according to the characteristics of spices: choose liquid nitrogen low-temperature crusher for high-oil spices (peppercorns, pepper); choose stainless steel high-speed crusher for high-fiber spices (cinnamon, ginger); choose air-cooled crusher for ordinary dry spices (star anise, cumin)

Choose according to production requirements: experimental/small batch (1-50kg/h); industrial mass production (100-1600kg/h)

Choose according to fineness requirements: coarse crushing (10-30 mesh) is suitable for preliminary processing of seasonings, and fine crushing (100-600 mesh) is suitable for high-end food and pharmaceutical industries.

Spices Coarse Crusher Manufacturer

Our company specializes in the production of spices coarse crushers, offering a variety of models (such as the SF-300, SF-500, and SF-800). These crushers are suitable for coarsely crushing spices such as chili peppers, star anise, cinnamon, and pepper. These crushers are constructed of high-quality stainless steel (304/316) or carbon steel, and custom materials are available. The crusher's feed size is ≤50mm, while the output size is adjustable from 0.5 to 5mm. The crusher boasts a capacity of 200 to 1000 kg/h, meeting diverse production needs. The machine is equipped with wear-resistant blades, variable speed control, and a dust removal system. Customization is available, so please feel free to contact us!

Herbs Coarse Crusher

Herbs Coarse Crusher Coarse crusher

Coarse crusher Universal Crusher

Universal Crusher