Industrial dry powder mixer

Efficiently and evenly mix various dry powder and granular materials, with a mixing uniformity of more than 95%

Capacity: 100-5000L/batch (common models: 200L, 500L, 1000L, 2000L, 4000L)

Power supply: three-phase 380V/50Hz (partially supports 110V/220V customization)

Discharging method: manual, pneumatic or electric valve

What is an industrial dry powder mixer

Industrial dry powder mixer Industrial dry powder mixer is a device used to evenly mix two or more powder materials. Since most industrial dry powders have fine particles, large specific gravity differences, and different fluidity, ordinary mixing equipment is difficult to achieve efficient and uniform mixing. The dry powder mixer uses structures such as spiral ribbons, plow blades or weightless paddles to make the materials flip, shear and convect in a short time, thereby achieving an ideal uniform mixing effect.

The equipment uses spiral, plowshare or zero-gravity mixing mechanisms, combined with high-speed rotation or convection principles, to achieve highly uniform mixing of materials in a short time (usually 2-15 minutes), and the mixing uniformity can reach more than 95%.

Structural types of industrial dry powder mixers

|

Classification dimensions |

horizontal dry powder mixer |

vertical dry powder mixer |

plowshare dry powder mixer |

zero-gravity dry powder mixer |

|

Picture |

|

|

|

|

|

Mixing time |

10~20 minutes |

10~30 minutes |

5~15 minutes |

1~5 minutes |

|

Delivery volume |

Medium to large (500-5000L/batch) |

Small to medium (100-2000L/batch) |

Medium to large (300-3000L/batch) |

Large Type (1000-10000L/batch) |

|

Conveying speed |

faster, about 3-10 minutes/batch |

slower, about 5-15 minutes/batch |

fast, about 2-8 minutes/batch |

fast, about 2-6 minutes/batch |

|

Applicable materials |

powder, granules, small amount of liquid mixture |

light powder, fine particles |

viscous or high-density powder, fiber material |

powder with large specific gravity difference, ultrafine powder |

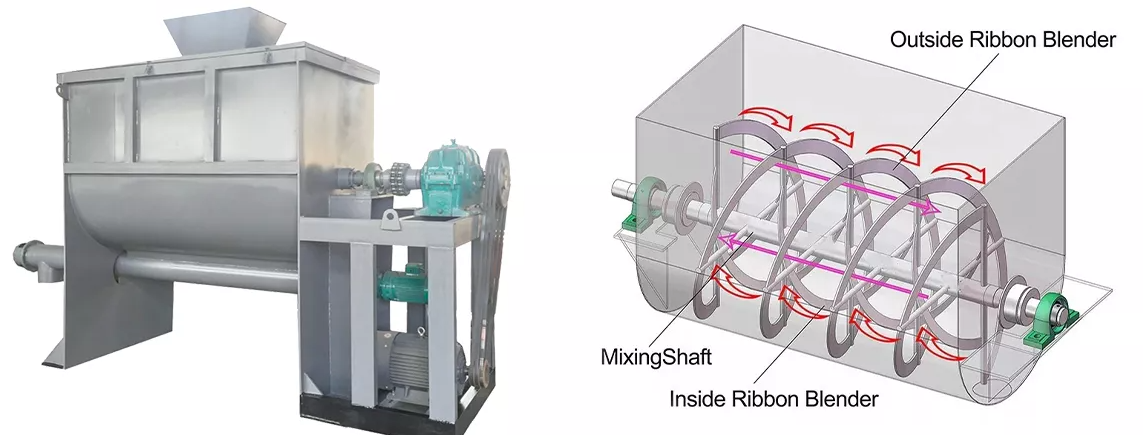

Horizontal dry powder mixer is a horizontal cylinder with two or more layers of spiral belt inside and outside. Vertical dry powder mixer generally uses the rapid rotation of the screw to lift the raw materials from the bottom of the barrel from the center to the top, and then scatters them back to the bottom in an umbrella-shaped fly, so that the raw materials roll up and down in the barrel and mix a large amount of raw materials evenly in a short time.

The plow blade dry powder mixer adopts a plow blade design, and multiple plow blade-shaped mixing blades are installed on the mixing shaft. When the plow blade rotates at high speed, it can throw, flip and shear the material, so that the material can be evenly mixed in a short time. It is often used in occasions with high requirements for mixing speed and uniformity.

There are two or more mixing shafts inside the gravity-free dry powder mixer, and mixing blades of different shapes and angles are installed on the shaft. When working, the mixing blades drive the material to make complex spatial movements, and achieve fast and uniform mixing in a weightless state, which is especially suitable for materials with large differences in mixing specific gravity and poor fluidity.

Working principle of industrial dry powder mixer

The working principle of industrial dry powder mixer is mainly based on mechanical force. Through specific mixing structure and movement mode, dry powder materials can be efficiently and evenly mixed in the container.

① Material input: Dry powder materials enter the mixing chamber of the mixer through the feed port (manual or automatic). Some equipment supports self-priming feeding to reduce manual operation.

② Movement of the mixing mechanism:

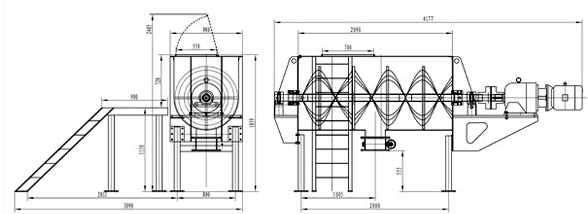

The horizontal dry powder mixer uses a horizontally placed mixing drum with a double-layer spiral belt or paddle inside. The main shaft is driven by a motor to rotate. The spiral belt pushes the material from one end to the other end in a convection manner. At the same time, the inner and outer spirals move in opposite directions to form tumbling and shearing to ensure that the material is fully mixed. The vertical dry powder mixer lifts the material from the bottom to the top through the rotation of the vertical spiral or stirring paddle, and then falls freely to form a circular mixing, which is suitable for light materials.

The plow blade dry powder mixer uses a high-speed rotating plow blade to cut and disperse the material, and at the same time combines the high-speed flying knife in the cavity to destroy the agglomeration of the material, which is suitable for sticky or high-density materials. The double-shaft paddles of the gravity-free dry powder mixer rotate in the opposite direction to produce a "weightless zone". The material is suspended and mixed under the action of convection and diffusion, which is particularly suitable for materials with large differences in specific gravity.

③Mixing process: Through physical actions such as convection, diffusion and shear, the material quickly flips and crosses in the mixing chamber to achieve uniform mixing, which is usually completed within 2-15 minutes, and the uniformity can reach more than 95%.

④Discharging: After mixing, the material is discharged through the bottom or side discharge port.

What are the advantages of industrial dry powder mixers?

High mixing uniformity: The powder material is fully diffused, convected and sheared in the cylinder by using the structure design of spiral ribbon, paddle, plow blade or weightless parabolic, and the uniformity error can be controlled within ±1%, which is suitable for products with high requirements for formula accuracy.

Fast mixing speed and high efficiency: A variety of power structures can achieve large-scale material mixing within a few minutes, especially the gravity-free mixer, which can complete the entire mixing process within 1 to 3 minutes, significantly improving production efficiency.

Wide range of materials: It can handle a variety of powder materials with good fluidity or strong viscosity and large specific gravity differences, and is even suitable for powder-powder and powder-liquid composite mixing to meet the needs of complex working conditions.

Technical parameters of industrial dry powder mixer

|

Model |

Total volume (L) |

Loading factor |

Motor power (kW) |

Mixing time (min) |

|

DSH-500 |

500 |

0.4-0.6 |

5.5 |

5-15 |

|

WLDH-1000 |

1000 |

0.4-0.6 |

7.5 |

8-20 |

|

LDH-2000 |

2000 |

0.4-0.6 |

11 |

10-20 |

|

WZL-3000 |

3000 |

0.4-0.6 |

15 |

15-30 |

What can industrial dry powder mixer be used for?

Industrial dry powder mixer is a special equipment for mixing and stirring powdered and granular materials. With its efficient mixing performance and wide applicability, it plays a key role in many industrial fields. Mix cement, sand, filler, additives, etc. in proportion to prepare uniform dry powder mortar to ensure bonding strength and weather resistance during construction. Mixing polystyrene particles and cement in thermal insulation mortar ensures the thermal conductivity and compressive strength of the insulation layer. Mixing powders of different chemical properties, such as uniformly dispersing pigments and fillers, ensures the consistency of coating coloring. When preparing pesticide powders, fully mix the active ingredients with the carrier to improve the uniformity of the efficacy.

Related application examples of industrial dry powder mixers

Dry powder mixers are required when manufacturing dry mortar or concrete additives. For example, in a premixed mortar production line, cement, sand, limestone powder and other additives (such as water reducers and thickeners) are mixed in specific proportions to meet different construction needs. This not only improves construction efficiency, but also improves the quality of buildings.

Price of industrial dry powder mixers

The price of industrial dry powder mixers varies depending on a variety of factors, including type, capacity, material and degree of automation. The price of industrial dry powder mixers varies depending on a variety of factors, including type, capacity, material and degree of automation. The price of industrial dry powder mixers varies depending on a variety of factors, including type, capacity, material and degree of automation.

|

Mixer type |

common volume range |

price range (USD) |

description |

|

Horizontal dry powder mixer |

100~5000L |

$1,400 ~ $11,200 |

widely used, suitable for conventional powder mixing |

|

Vertical dry powder mixer |

200~3000L |

$1,100 ~ $8,400 |

small footprint, simple structure, suitable for small and medium production |

|

Plowshare dry powder mixer |

500~6000L |

$4,200 ~ $21,000 |

strong mixing, suitable for sticky or difficult to mix materials |

|

Gravityless dry powder mixer |

500~10000L |

$5,600 ~ $28,000 |

efficient and uniform mixing, commonly used in large production lines |