Automatic powder packaging machine production line

Monday June-09 2025 16:08:04

In modern industrial production, the packaging efficiency and packaging accuracy of powder materials are directly related to product quality and market competitiveness. The fully automatic powder packaging machine production line (different models can be selected according to demand, such as 1-5kg, 5-25kg packaging specifications) has the advantages of high-precision metering and stable output (up to 300-800 bags per hour), which is an intelligent solution to meet this demand. The equipment integrates automatic metering, automatic filling, automatic sealing, and automatic conveying, realizing unmanned operation of the entire process from raw material feeding to finished product discharge, greatly improving production efficiency and packaging consistency.

Technical principle of automatic powder packaging machine production line

The fully automatic powder packaging machine production line integrates feeding, metering, filling, sealing, labeling and coding functions, and adopts a PLC control system to achieve full process automation. Taking the XH-LA2 semi-automatic powder filling and packaging machine as an example, the equipment consists of a filling host, an electrical box, a touch screen PLC and an electronic scale. It is driven by a servo motor, and the mixing system uses a maintenance-free reduction motor, which has stable operation and high packaging accuracy. The metering methods include screw metering and electronic weighing, which are suitable for powders with good fluidity or high precision. The packaging process supports 10 sets of formula storage, which is convenient for quick switching and improves production efficiency and flexibility.

The core advantages of the automatic powder packaging machine production line

The fully automatic powder packaging machine production line is efficient and accurate, compatible with a variety of packaging, and supports intelligent monitoring and flexible adjustment:

Efficient production: The fully automatic powder packaging machine production line supports rapid mold replacement and adjustment of packaging size through modular design to meet the production needs of multiple categories. For example, the packaging speed of a production line can reach 20-50 bags/minute, which is several times higher than the efficiency of traditional manual packaging.

Accurate metering: High-precision sensors and servo control systems are used to ensure that the weight deviation of each bag of product is controlled within ±0.5%, meeting the strict standards of the pharmaceutical, food and other industries.

Flexible adaptation: The production line is compatible with packaging bags of different materials (such as PA/PE, aluminum foil composite film), and supports a variety of packaging forms such as back-sealed bags, three-side sealed bags, and four-side sealed bags to meet diverse market needs.

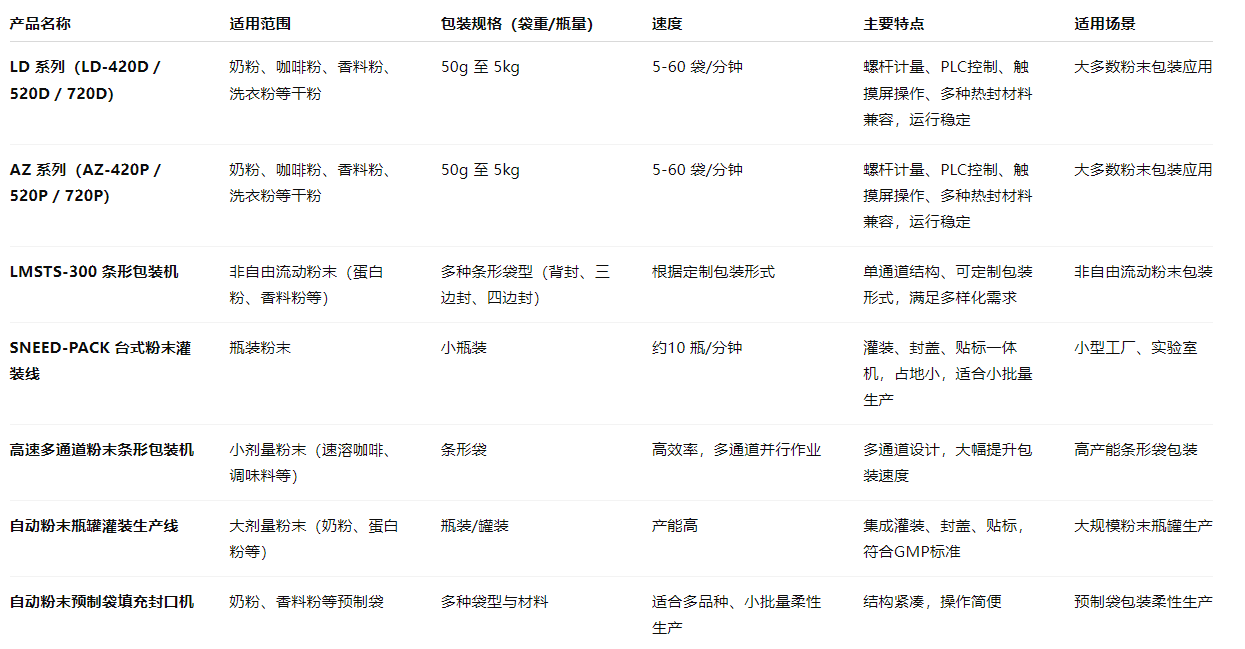

Automatic powder packaging machine production line common models

Automatic powder packaging machine production line models are diverse, suitable for different production capacities and packaging needs. Common models include:

Application scenarios of Automatic powder packaging machine production line

Fully automatic powder packaging machine production lines are widely used in food, medicine, chemical and other fields. In the food industry, milk powder, coffee powder, condiments, etc. can be efficiently packaged; the pharmaceutical industry is used for aseptic packaging of powders such as medicines, veterinary drugs, and health products; the chemical industry is suitable for dyes, additives, pesticides and other materials to ensure packaging safety and environmental protection. For example, after a pharmaceutical company introduced this production line, its production capacity increased by 40%, and it met the GMP clean workshop standards through aseptic air ducts and UV sterilization modules, significantly enhancing product competitiveness and market recognition.

Fully automatic powder packaging machine production line is an important tool to improve the efficiency and quality of powder packaging of enterprises. With its advantages of high automation, high precision, easy operation, and scalability, it has become the preferred equipment for many powder product manufacturers. When purchasing, enterprises should choose the appropriate model based on their own material characteristics, production needs and plant layout, and pay attention to the stability and after-sales service of the equipment, so as to achieve a double improvement in packaging efficiency and quality.