Vacuum feeder

Vacuum feeder realizes closed material transmission with vacuum suction, effectively avoiding dust flying and material pollution. It is suitable for many industries such as food, pharmaceuticals, and chemicals. It can also be customized on demand to meet the personalized needs of different production scenarios.

Power: 1.5-5.5kw (customizable)

Dimensions (length * width * height): Depends on the specific model

Material: Stainless steel / carbon steel

Voltage: 220V / 380V / 415V or according to order

Customization: Acceptable

Type: Pneumatic / Electric / Continuous

Core components: Motor, bearing, gear, pump, gearbox, engine

Applicable industries: building materials stores, manufacturing plants, food and beverage plants, farms, food stores, printing plants, construction projects, energy and mining industries.

What is a Vacuum feeder?

Vacuum feeder adopts advanced negative pressure conveying technology to realize the automatic dust-free handling of powdered and granular materials. The modular design supports non-standard customization and can be adapted to special requirements such as 316L stainless steel, explosion-proof, and aseptic cleaning. Compared with traditional conveying methods, the vacuum feeder has the advantages of low energy consumption, low breakage rate, and thorough cleaning. It can not only meet the short-distance precision conveying, but also can be expanded to continuous large-scale production. It is an ideal choice for modern smart factories to improve efficiency and ensure quality.

Vacuum feeder type

Vacuum feeders are mainly divided into three types: intermittent, continuous, and explosion-proof. They meet the efficiency requirements of the pharmaceutical, food, chemical and other industries, support customized configuration, and are suitable for the characteristics of various powder and granular materials.

Intermittent vacuum feeder: adopts batch operation mode and completes material transportation through the "suction-separation-discharge" cycle process. The working cycle is 3-10 minutes/time, and the double-bin alternating system can achieve quasi-continuous feeding. This model is particularly suitable for small and medium-sized batch production scenarios.

Continuous vacuum feeder: Through the rotary valve or double butterfly valve system, the material is continuously transported, and the transportation efficiency can reach 15 tons/hour. It is particularly suitable for large-scale continuous production, such as food additive ingredients, plastic granulation and other scenarios.

Explosion-proof vacuum feeder: specially designed for hazardous environments such as chemical and pharmaceutical industries, and complies with international explosion-proof standards such as ATEX and IECEx. Pneumatic drive can be used instead of motors for special working conditions to completely eliminate electric sparks.

Vacuum feeder advantages

Negative pressure adsorption technology is used to achieve dust-free automatic conveying of powders and particles, eliminating pollution and waste; modular design supports customization, helping enterprises to upgrade intelligently!

Enclosed dust-free conveying system: adopts a fully enclosed pipeline design, which isolates the outside world from material inhalation to discharge, effectively preventing dust leakage.

Flexible spatial adaptability: With strong negative pressure conveying capacity, the vacuum feeder can achieve a horizontal conveying range of 30-50 meters and a vertical lifting range of 15-20 meters. The unique pipeline layout design can bypass equipment obstacles and adapt to complex plant structures.

Gentle conveying and low breakage rate: The use of adjustable airflow control technology can achieve gentle handling of brittle materials by optimizing vacuum degree and conveying speed. Compared with mechanical conveying methods, the particle breakage rate of vacuum conveying is reduced by more than 60%.

Intelligent automation integration: equipped with advanced PLC control system, it can achieve seamless linkage with packaging machines, mixers and other equipment.

Working principle of Vacuum feeder

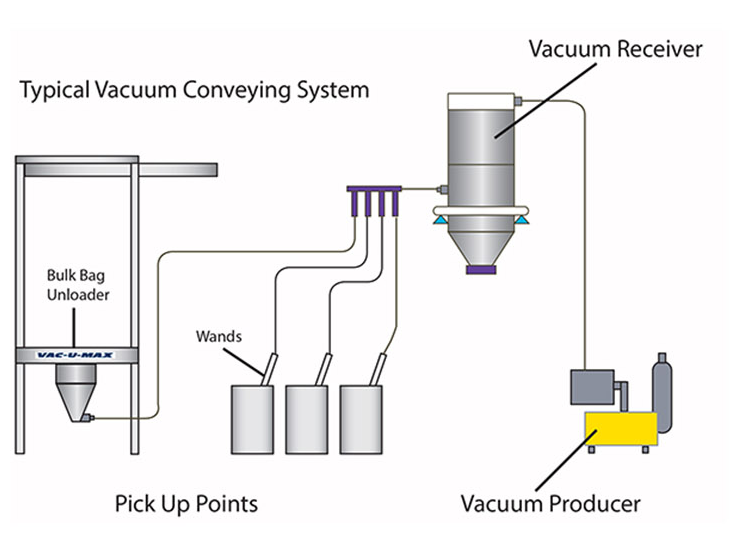

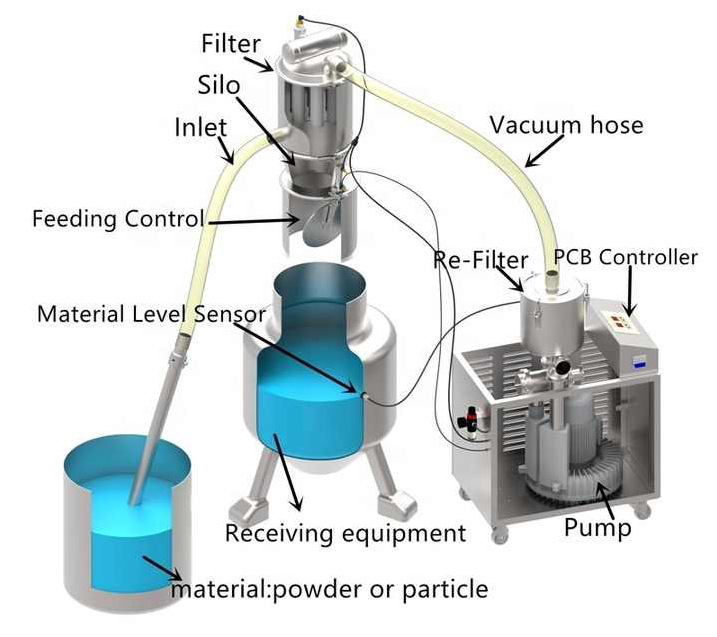

The vacuum feeder uses a vacuum pump or fan to generate negative pressure in a closed pipe to adsorb materials, and transports the powder and particles from the starting point (such as silos, packaging bags) through the pipe to the target container, and then achieves gas-solid separation through a high-efficiency filter - the material falls into the container and the clean air is discharged. The whole process can be set to automatic circulation mode, which can not only achieve continuous and stable feeding, but also intermittent operation on demand, perfectly adapting to the material transportation needs of different production scenarios.

Vacuum feeder composition structure

The vacuum feeder consists of a vacuum power system, a sealed conveying pipeline, a high-efficiency filter, an intelligent control system, etc., and adopts a modular design to ensure that the powder and particle materials complete the entire process of adsorption-separation-unloading in a closed environment.

Vacuum pump/fan system: As the core power source of the equipment, the vacuum pump (electric) or fan (pneumatic) mechanically establishes a stable negative pressure environment in a closed pipe.

Intelligent suction pipeline system: The conveying pipeline made of food-grade stainless steel or antistatic PE material, combined with the patented Venturi suction nozzle, forms an efficient conveying channel.

Multi-stage separation and filtration device: A double filtration system consisting of a primary stainless steel sintered filter element and a high-efficiency PTFE coated filter bag, with a filtration accuracy of up to 0.3μm.

Intelligent control system: It adopts an industrial-grade PLC + 10-inch touch screen combination, integrating functions such as material metering, fault diagnosis, and energy consumption management.

Modular silo system: Receiving containers of different capacities (50L-2000L) are configured according to the application scenario, and a weighing module can be optionally equipped to achieve accurate metering. The no-dead-angle design facilitates thorough cleaning and meets CIP/SIP cleaning requirements.

Technical parameters

|

Model |

Motor Power (KW) |

Conveying Capacity (Koh) |

|

HCSL - 1 |

1.5 |

400 |

|

HCSL - 2 |

2.2 |

600 |

|

HCSL - 3 |

3 |

1200 |

|

HCSL - 4 |

5.5 |

2500 |

|

HCSL - 6 |

5.5 |

3200 |

|

HCSL - 7 |

7.5 |

6000 |

|

HCSL - 10-6 |

7.5 |

6000 (When the conveying distance is 10 meters) |

|

HCSL - 20-5 |

11 |

5000 (When the conveying distance is 20 meters) |

What are the application scenarios of Vacuum feeder?

The vacuum feeder is designed for powder and granular materials and is widely used in scenarios such as pharmaceutical raw material transportation, food additive metering, chemical powder explosion-proof transportation, and lithium battery material dust-free transportation.

Pharmaceutical industry: Vacuum feeders play a key role in the pharmaceutical field. For the transportation of raw materials, they can realize the dust-free transfer of API raw materials, fully meet the GMP aseptic standards, ensure the closed transportation of tablet particles and capsule powders, and effectively avoid cross contamination.

Food industry: safe transportation of powdered raw materials such as flour, milk powder, seasonings, etc.; accurate metering of food additives to ensure accurate ratios.

Chemical industry: vacuum feeders provide explosion-proof transportation solutions for high-risk materials, ensure safe transportation of flammable and explosive powders, and achieve high-purity transfer of catalysts, dyes, etc.; in the face of nanomaterials, effectively deal with the anti-agglomeration problem of ultrafine powders such as carbon nanotubes.

New energy industry: vacuum feeders strictly control the moisture content of positive and negative electrode raw materials of lithium battery materials to ensure battery performance.

Vacuum feeder vs. other conveying methods

Compared with pneumatic conveying, vacuum feeders have lower energy consumption and more thorough dust prevention; compared with spiral/belt conveyors, they have no mechanical friction to avoid material breakage and contamination.

Vacuum feeder vs. pneumatic conveying system

Although pneumatic conveying is suitable for large-scale transportation over long distances (>50 meters), it has problems such as high particle breakage rate (about 5%-15%) and severe pipe wear. The vacuum feeder can achieve gentle conveying through adjustable airflow control to ensure the integrity of brittle materials. In addition, the vacuum feeder adopts a fully enclosed design to prevent dust leakage.

Vacuum feeder vs. mechanical conveying (screw, belt)

Screw conveyors are prone to material extrusion and crushing, and are difficult to clean, with a residual rate of up to 2%-5%; while vacuum feeders use smooth pipes + pulse backwash cleaning, and the residual rate can be controlled below 0.1%, meeting the hygiene requirements of the food and pharmaceutical industries. In addition, the vacuum feeder has a flexible layout and can easily bypass equipment obstacles, while mechanical conveying is limited by a fixed installation structure and is difficult to adapt to the conveying needs of multi-position and complex factories.

Selection factors of vacuum feeder

Selection needs to comprehensively consider the particle size, density and fluidity of the material, match the conveying volume (intermittent/continuous) and distance (horizontal/vertical), and select suitable stainless steel/plastic materials to ensure efficient, safe and compliant powder conveying solutions.

Material property analysis: The particle size, density, fluidity and humidity of the material are the key factors affecting the selection and conveying efficiency of the vacuum feeder. Fine powders need high-precision filtration to prevent clogging, and large particles need to be designed to prevent crushing; lightweight materials need to adjust the air flow speed, and high-density materials need to enhance the vacuum degree; materials that are easy to form arches need to be equipped with vibration or fluidization devices; hygroscopic materials need a dry air system to prevent agglomeration.

Conveying volume and distance requirements: In terms of conveying volume, intermittent type is suitable for small batches (<1t/h), and continuous type can meet the high-production requirements of 5-15t/h. In terms of conveying distance, economical fans can be used for short distances (<15m), and high-pressure vacuum pumps are required for long distances (>30m).

Equipment material selection: Material selection needs to be determined according to material characteristics and usage scenarios. Stainless steel is corrosion-resistant and suitable for pharmaceutical, food and acid-base environments; carbon steel is economical and durable and suitable for non-corrosive materials.

Vacuum feeder manufacturer

As a professional vacuum feeder manufacturer, we rely on more than 10 years of industry experience to provide efficient and reliable powder and particle conveying solutions for pharmaceutical, food, chemical and new energy fields. We not only provide standard models, but also focus on in-depth non-standard customization services. We can customize 304/316L stainless steel or food-grade plastic equipment according to customer needs, and equip it with special functions such as explosion-proof (ATEX certification), aseptic cleaning (CIP/SIP) and intelligent joint control. Through modular design and flexible production system, we have successfully provided personalized solutions for many companies. From laboratory small machines to industrial large units, they can accurately match various complex working conditions, ensure the efficiency, safety and cleanliness of material conveying, and help customers achieve intelligent production upgrades.

Vacuum feeders are ideal for powder and particle conveying in modern industry with their high efficiency and cleanliness, especially in the field of process safety and hygiene. In actual applications, the design needs to be customized according to material characteristics and production requirements.