Cyclone pulse vacuum crusher

Grinding fineness: 20 - 500 mesh

Production capacity: 0 - 2000 kg/h

Main motor power: 5.5 - 75 kW

Dust collector air volume: 500 - 15000 m³/h

What is Cyclone pulse vacuum crusher?

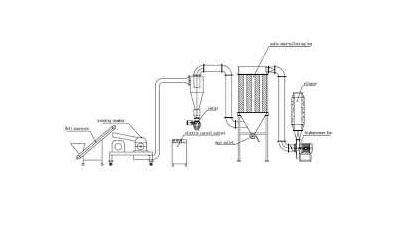

Cyclone pulse vacuum crusher is a modern powder processing equipment that integrates crushing, separation and dust removal. It adopts pulse dust removal technology to ensure that there is no dust spillage during the production process. It is suitable for the high-standard production needs of food, pharmaceutical, chemical, magnetic materials and other industries.

The equipment consists of a crushing main unit, a cyclone separator, a pulse dust removal box, an induced draft fan, etc., which can realize continuous feeding, automatic crushing, efficient separation, and dust recovery, greatly improving production efficiency and environmental protection performance.

What types of Cyclone pulse vacuum crusher are there?

Cyclone pulse vacuum crusher is available in carbon steel and stainless steel, which can be selected according to the application industry

304 stainless steel type: meets food grade and pharmaceutical grade hygiene standards, corrosion-resistant and easy to clean.

Carbon steel type: suitable for industries with non-strict hygiene requirements such as chemical industry and metallurgy.

Why choose Cyclone pulse vacuum crusher?

Dust-free production: The dust recovery rate of the pulse dust removal system is ≥99%, which meets GMP and FDA standards.

Efficient crushing: adopts high-speed impact + shear crushing, and the fineness is adjustable (20-400 mesh).

Energy saving and environmental protection: Compared with traditional crushers, energy consumption is reduced by 30%, and exhaust gas emissions meet the standards.

Continuous operation: automatic feeding + discharging, supporting 24-hour uninterrupted production.

How does Cyclone pulse vacuum crusher work?

The working process of Cyclone pulse vacuum crusher is divided into four stages: crushing, separation, dust removal, and discharging, as follows

Crushing stage: the material enters the crushing chamber and is crushed by the high-speed rotating hammer/toothed disc.

Separation stage: the crushed material enters the cyclone separator under the action of centrifugal force + fan gravity.

Dust removal stage: fine dust is captured by the pulse bag dust collector and clean air is discharged.

Discharging stage: the finished product is automatically discharged by turning off the fan, and the dust is recycled and reused.

Cyclone pulse vacuum crusher technical parameters

| Model | Production capacity (kg/h) | Feed particle size (mm) | Grinding fineness (mesh) | Motor power (kW) | Weight (kg) |

| WF-250 | 50-100 | ≤5 | 80-400 | 5.5 (crushing) + 2.2 (dust removal) | 580 |

| WF-450 | 100-500 | ≤5 | 80-400 | 15 (Crush) + 4 (Dust) | 1200 |

| WF-850 | 500-2500 | ≤5 | 80-400 | 37 (Crush) +11 (Dust) | 3000 |

What are the applications of Cyclone pulse vacuum crusher?

Chemical industry: pigments, resins, catalysts, rubber additives (such as carbon black, ABS particles)

Food and medicine: Chinese medicinal materials (panax notoginseng, ganoderma), health food raw materials (spirulina, inulin), pharmaceutical intermediates (API micronization)

Mineral processing: kaolin, graphite, silicon micropowder (purity requirement ≥99.5%)

New energy: lithium battery positive electrode materials (lithium iron phosphate, ternary lithium), negative electrode materials (graphite negative electrode pretreatment)

Others: pesticide wettable powder, ceramic powder, electronic grade high purity alumina

Sugested Products

Related news

Sieving Machine

Conveying equipment

Bucket Elevator

Mixer

Packaging Machine

E-mail:

sale@xxdahan.com

WhatsApp:

+86 15836198876

Add:

Yanjin county forest park gate to the west 1000 meters north road

Chinese Herb Grinder Machine

Chinese Herb Grinder Machine Pin Grinding Crusher

Pin Grinding Crusher Universal Crusher

Universal Crusher Spice Crusher

Spice Crusher