Pin Grinding Crusher

Rotor diameter: 320mm

Rotor speed: 3000-12000rpm (adjustable)

Processing capacity: 100-1000kg/h (depending on material characteristics)

Fineness range: D50: 2-50μm; D90: 5-100μm (adjustable)

Power configuration: Main motor 55kW, total system power 75kW

What is Pin Grinding Crusher?

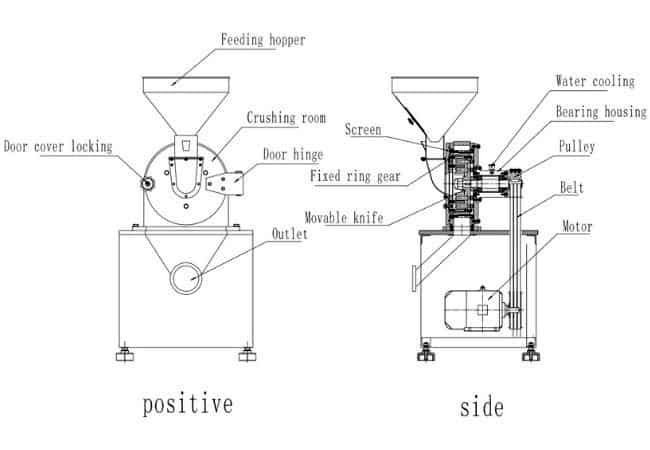

Pin Grinding Crusher adopts the principle of high-speed impact and shearing compound, and realizes ultra-fine grinding of materials through a precisely designed rotor and stator needle bar system. The material is transported to the grinding chamber by the feeding system, and is subjected to repeated impact, shearing and grinding between the high-speed rotating rotor needle bar (speed can reach 250m/s) and the fixed gear ring, and finally discharged through the precision screen to obtain uniform ultra-fine powder.

Compared with traditional grinding equipment, our Pin Grinding Crusher has the following unique working characteristics:

Fully enclosed negative pressure system: patented vacuum environment operation (0/20ATEX certification), completely exclude oxygen, eliminate explosion risks, especially suitable for flammable and explosive material processing

Low temperature crushing technology: extremely low friction heat, no liquid nitrogen cooling, process temperature rise is controlled below 50℃, perfectly protect heat-sensitive components

Self-cleaning design: special rotor structure avoids material accumulation, with quick-release pipe connection, to achieve fast material change and cleaning

What types of Pin Grinding Crusher are there?

Pin Grinding Crusher can be divided into standard type, ultra-fine type, low-temperature type, and explosion-proof type according to different processing capabilities, discharge fineness requirements and application fields.

Standard Pin Grinding Crusher: It has strong versatility and is suitable for fine grinding of a variety of medium-hard materials.

Ultra-fine Pin Grinding Crusher: It adopts more precise grinding elements and higher rotation speed to achieve ultra-fine grinding of micron or even sub-micron level.

Low-temperature Pin Grinding Crusher: It is equipped with a cooling system to effectively control the temperature rise during the grinding process and is suitable for the crushing of temperature-sensitive materials.

Explosion-proof Pin Grinding Crusher: It adopts a special explosion-proof design to meet the crushing needs of flammable and explosive materials to ensure production safety.

What are the advantages of Pin Grinding Crusher?

High crushing efficiency: The particle size distribution is precisely controlled, the PSD range is as low as D90<6μm, the processing capacity is as high as 1000 kg per hour, the energy consumption is reduced by more than 30%, and no additional cyclone separator is required.

Narrow particle size distribution: By precisely controlling the grinding gap and rotation speed, powders with uniform particle size distribution and controllable fineness can be obtained.

Wide range of applications: It can handle a variety of materials of different properties, including chemicals, medicines, foods, minerals, feeds, etc.

Easy operation and maintenance: The structural design is reasonable, easy to install, operate, clean and maintain, and reduces labor costs.

How does Pin Grinding Crusher work?

The working principle of our Needle-Type Grinding Mill is based on the high-speed rotation of a set of needles. As the material enters the grinding chamber, it is subjected to intense impact and shearing forces from the rapidly rotating needles. This continuous action breaks down the material into fine particles, which are then discharged through a sieve or cyclone separator.

What are the applications of Pin Grinding Crusher?

1. Pharmaceutical industry: Ultrafine grinding of active pharmaceutical ingredients (API) to improve bioavailability; cell wall breaking of traditional Chinese medicine, with a wall breaking rate of ≥98%, and a 3-5-fold increase in drug efficacy; micronization of poorly soluble drugs to improve dissolution; sterile powder production in compliance with FDA/cGMP requirements

2. Food and health products: Ultrafine processing of functional food ingredients (such as Ganoderma lucidum spores and Cordyceps sinensis); micronization of flavors and spices to enhance flavor release; refinement of dietary fiber to improve food taste; uniform dispersion of nutritional enhancers

3. Chemical and new materials: Ultrafine dispersion of high-performance pigments, with a particle size of up to 0.2μm; uniform grinding of battery materials to improve electrochemical performance; modification of polymer materials; fine processing of catalyst carriers

4. Other special applications: preparation of metal powders, processing of electronic materials, processing of ceramic raw materials, fine processing of minerals

Pin Grinding Crusher Customer Case

API production line for international pharmaceutical giants

Customer needs: A multinational pharmaceutical company needs to establish an anticancer drug API micronization production line that meets FDA requirements, requiring D90 < 10μm, production capacity ≥ 500kg/h, and no pollution risk throughout the process

Solution: Provide PMV-320ATEX explosion-proof model, equipped with a fully enclosed nitrogen protection system

Results: Production capacity reaches 600kg/h, particle size D90 = 8.5μm, successfully passed FDA audit

Special pigment production

Customer needs: A high-end pigment manufacturer needs to reduce the product fineness from D50 = 5μm to D50 = 1.5μm

Solution: Use ceramic lined pin grinder, special rotor design

Results: Production capacity 300kg/h, D50 = 1.2μm, chromaticity index increased by 30%

Sugested Products

Related news

Sieving Machine

Conveying equipment

Bucket Elevator

Mixer

Packaging Machine

E-mail:

sale@xxdahan.com

WhatsApp:

+86 15836198876

Add:

Yanjin county forest park gate to the west 1000 meters north road

Chinese Herb Grinder Machine

Chinese Herb Grinder Machine Coarse crusher

Coarse crusher Universal Crusher

Universal Crusher Spice Crusher

Spice Crusher