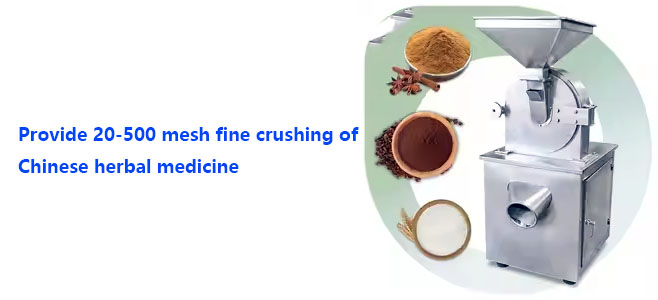

Chinese Herb Grinder Machine

Output: 10-1000kg/h

Fineness: 20-2000 mesh

Power: 2.2-60KW

What is Chinese Herb Grinder Machine?

The Chinese Herb Grinder Machine is a specialized grinding equipment developed specifically for the physical properties of Chinese herbal medicines. It can efficiently grind Chinese herbal medicines of different materials such as roots, stems, leaves, and flowers to ensure the complete release of effective ingredients. Compared with traditional general grinders, it has better adaptability to fibrous and oily medicinal materials. Chinese herbal medicines require special grinding processes due to their special tissue structure (such as cell wall structure) and active ingredient protection requirements. Our Chinese herbal medicine grinder adopts air-cooled design and graded grinding principle, which can complete the whole process from coarse grinding to ultra-fine grinding in a low temperature environment (<45℃), effectively protecting the heat-sensitive components in the medicinal materials.

This type of equipment is particularly suitable for processing the following types of Chinese herbal medicines:

Roots and stems: such as ginseng, astragalus, licorice, etc.

Leaves and whole herbs: such as mint, wormwood, dandelion, etc.

Fruit seeds: such as wolfberry, schisandra, cassia seed, etc.

Minerals: such as gypsum, cinnabar, etc.

Precious medicinal materials: such as American ginseng, cordyceps, etc.

The entire equipment is made of 304 stainless steel, which meets the GMP pharmaceutical production standards to ensure that there is no risk of heavy metal pollution during the crushing process. The part in contact with the material is mirror polished to avoid material residue and cross contamination

What types of Chinese Herb Grinder Machine are there?

| Type | Applicable scenarios | Fineness range (mesh) | Output | Core advantages |

|

Chinese Herb Grinder Machine for laboratory |

Pharmacy processing, laboratory sample preparation, home health care use | 60-200 | 200-400g/time | Low noise (<60 decibels), no dust, fast crushing speed (30 seconds-2 minutes) |

| Production-type Chinese Herb Grinder Machine | Small and medium-sized Chinese medicine factories, decoction processing enterprises, health care products production | 20-250 | 20-300kg/h | Low temperature rise (≤55℃), high dust collection rate (99.5%),can handle oily materials |

| Ultrafine crushing Chinese Herb Grinder Machine | Large-scale production of Chinese medicine extracts, ultrafine powder preparation processing | 100-2000 | 150-5000kg/h | Narrow particle size distribution, no large particles, adjustable particle size |

| Special models | Fiber-specific, oil-containing, mineral-specific and other specific medicinal materials processing | Customized according to needs | Customized according to needs | Targeted solution to special problems |

What are the advantages of Chinese Herb Grinder Machine?

Low temperature crushing: The air cooling/water cooling system controls the temperature ≤55℃, retaining 2510 active ingredients of medicinal materials.

Efficient grading: No screen design, through centrifugal grading to achieve 20-250 mesh (up to 2000 mesh) fineness precision adjustment.

Safety and environmental protection: Fully enclosed negative pressure operation, dust collection rate ≥99.5%, in line with pharmaceutical grade GMP standards.

Intelligent energy saving: Motor power optimization (11-200kW), energy consumption is 30% lower than traditional equipment.

Comparison between Chinese Herb Grinder Machine and Traditional Grinder

| Comparison items | Special Grinder | Traditional Grinder |

| Temperature Control | <45℃ | 60-80℃ |

| Fineness Adjustment | 20-2000 mesh steplessly adjustable | Fixed mesh number |

| Fiber Processing | Special shear blade, high efficiency | Easy to entangle and clog |

| Oily materials | Anti-adhesion design, stable operation | Severe wall adhesion |

| Dust control | Fully enclosed, collection rate >99% | Open, large dust |

| Energy consumption ratio | 0.8-1.2kWh/100kg | 1.5-2kWh/100kg |

| Medicinal material loss | <1% | 5-15% |

How does Chinese Herb Grinder Machine work?

When the Chinese Herb Grinder Machine is working, Chinese herbs enter the crushing chamber through the hopper, and the high-speed rotating blade or impact hammer cuts and impacts the Chinese herbs into particles. The grading wheel selects qualified powder according to the target fineness, and the unqualified particles return to continue to be crushed. The negative pressure airflow transports the finished product to the collection box, and the dust is recovered by the bag dust collector, and there is no pollution throughout the process.

What are the applications of Chinese Herb Grinder Machine?

Chinese herbal medicine grinders are widely used in all aspects of the traditional Chinese medicine industry due to their excellent performance characteristics:

1. Processing of Chinese herbal medicine slices

Coarse particle preparation: produce 20-60 mesh slice granules for traditional decoction, which can increase the dissolution rate of effective ingredients by more than 30% compared with slice slices

Directly take powder: prepare 80-120 mesh fine powder, suitable for traditional powders such as Panax notoginseng powder and pearl powder

Broken wall slices: through ultrafine grinding of more than 300 mesh, cell-level wall breaking is achieved, and bioavailability is increased by 50%-200%

2. Production of Chinese patent medicines

Pill raw material processing: grind various medicinal materials to 100-150 mesh to ensure uniform texture of pills

Tablet excipient processing: micronize excipients (such as microcrystalline cellulose) to improve tableting performance

Capsule fillers: ultrafine grinding (300-500 mesh) makes filling tighter and content more accurate

3. Pretreatment of Chinese herbal medicine extraction

Increase specific surface area: crush to 40-80 mesh, so that the extraction efficiency is increased by 40%-60%

Cell wall pretreatment: After ultrafine grinding of some medicinal materials, the extraction time can be shortened by more than 50%

Enzymatic hydrolysis assistance: fine grinding is conducive to the contact between enzyme and substrate, and improves the efficiency of enzymatic hydrolysis

4. Application of health products and food

Medicine and food products: such as wolfberry powder, yam powder and other functional food raw materials processing

Substitute tea production: grind various herbal raw materials to appropriate particle size for easy packaging and brewing

Special nutritional products: such as placenta powder, deer antler powder and other high-end health products fine processing

5. Clinical and scientific research uses

Hospital preparation room: small batch processing of prescription drugs

Laboratory research: provide samples of different particle sizes to study the relationship between particle size and drug efficacy

Quality standard formulation: establish grinding process standards for various medicinal materials

| Target fineness (mesh) | Applicable medicinal material type | Unit energy consumption (kWh/kg) | Typical output (kg/h) | Temperature effect (ΔT) |

| 20-60 | Coarse particles for decoction | 0.05-0.1 | 300-500 | <10℃ |

| 80-120 | Conventional powder | 0.1-0.15 | 200-300 | 10-15℃ |

| 150-200 | Fine powder preparation | 0.15-0.25 | 100-200 | 15-20℃ |

| 300-500 | Ultrafine powder | 0.3-0.5 | 50-100 | 20-25℃ |

| 800-2000 | Wall-breaking grade micropowder | 0.8-1.2 | 10-30 | 25-30℃ |

Chinese Herb Grinder Machine customer case

Ginseng project of a listed pharmaceutical company: Grind ginseng to 300 mesh for oral liquid raw materials

Solution: Use KFC-400 ultrafine pulverizer with liquid nitrogen cooling system

Effect: Ginseng saponin retention rate>95%, production capacity reaches 200kg/shift1

Processing of Panax notoginseng powder in TCM clinic: On-site processing of high-quality Panax notoginseng powder (200 mesh)

Solution: Equipped with YF-130A special pulverizer

Effect: 15-20kg can be processed per hour, and the powder temperature rise is <10℃10

Pretreatment of plant extraction enterprises: Grind raw materials such as astragalus to 60 mesh to improve the extraction rate

Solution: WF-300 production line

Effect: Extraction time is shortened by 30%, and the yield is increased by 18%4

Processing of ethnic minority medicinal materials: Processing special sticky medicinal materials (such as mineral medicines commonly used in Tibetan medicine)

Solution: Customized anti-adhesion pulverizer unit

Effect: Continuous work for 8 hours without clogging, stable fineness

Sugested Products

Related news

Sieving Machine

Conveying equipment

Bucket Elevator

Mixer

Packaging Machine

E-mail:

sale@xxdahan.com

WhatsApp:

+86 15836198876

Add:

Yanjin county forest park gate to the west 1000 meters north road

Micro-crushing machine

Micro-crushing machine Coarse crusher

Coarse crusher Universal Crusher

Universal Crusher Spice Crusher

Spice Crusher