Self-dusting pulverizer

Production capacity: 60-500kg/h

Discharge particle size: 12-120 mesh

What is a self-dusting pulverizer?

Self-dusting pulverizer is a high-efficiency equipment that integrates crushing and dust removal, and is widely used in pharmaceutical, chemical, food and other industries. It adopts a closed structure and automatically recycles dust during the crushing process to ensure that the production environment is pollution-free and meets GMP standards. It is particularly suitable for production scenarios with high requirements for cleanliness.

Compared with traditional crushers, Self-dusting pulverizer has the advantages of high degree of automation, simple operation, energy saving and environmental protection, which can greatly improve material utilization and reduce enterprise production costs.

What types of self-dusting pulverizers are there?

Self-dusting pulverizer can be divided into vertical, horizontal, high-speed and explosion-proof according to different structures and application scenarios.

Vertical Self-dusting pulverizer: suitable for fine crushing, such as medicines, food additives, etc.

Horizontal Self-dusting pulverizer: suitable for high-yield crushing, such as chemical raw materials, feed, etc.

High-speed Self-dusting pulverizer: suitable for ultra-fine crushing, such as metal powders, pigments, etc.

Explosion-proof Self-dusting pulverizer: suitable for flammable and explosive materials, such as certain chemical raw materials

What are the characteristics of a self-dusting pulverizer?

No dust pollution: using bag dust removal + cyclone separation technology, dust recovery rate ≥ 99%, ensuring a clean production environment.

High efficiency and energy saving: optimizing blade design, crushing efficiency increased by 30%, energy consumption reduced by 20%.

All stainless steel material: in line with GMP standards, corrosion-resistant, easy to clean, suitable for food and pharmaceutical industries.

Intelligent control: some models support PLC automatic adjustment, realizing one-button start and stop, fault alarm and other functions.

Low noise operation: adopting shock absorption design, noise ≤ 75dB, improving working environment

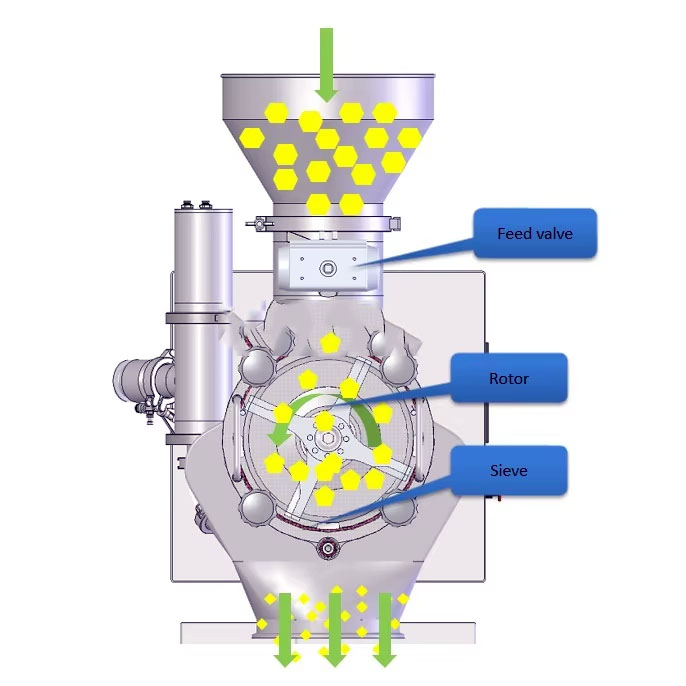

How does a self-dusting pulverizer work?

When the self-dusting pulverizer is working, the material enters the crushing chamber through the hopper. Under the interaction of the high-speed rotating blade and the fixed toothed disc, the material is crushed by shearing, impacting and friction. The crushed material enters the capture bag under the action of centrifugal force, the dust is recovered after being filtered by the bag, and the clean air is discharged. The material that meets the particle size is discharged through the screen, and the coarse particles continue to be crushed.

Self-dusting pulverizer parameters

| Model | Production capacity (kg/h) | Feed size (mm) | Discharge size (mesh) | Power (kW) | Size (mm) |

| JB-20 | 60-180 | ≤6 | 12-120 | 5.88 | 1200×1150×2570 |

| JB-30 | 100-400 | ≤10 | 12-120 | 9.38 | 1250×1200×2570 |

| JB-40 | 200-800 | ≤12 | 12-120 | 12.88 | 1400×1350×2890 |

| GXF-30B | 100-300 | ≤10 | 60-120 | 5.5 | 1200×650×1650 |

Self-dusting pulverizer application

Pharmaceutical industry: crushing Chinese and Western medicine particles to ensure no cross contamination.

Food industry: processing sugar powder, milk powder, starch, etc., in compliance with food safety standards.

Chemical industry: crushing resin, pigment, titanium dioxide, etc., explosion-proof design to ensure safety.

New energy industry: crushing lithium battery materials, dust controllable.

Environmental protection industry: recycling and reuse of construction waste and slag

Sugested Products

Related news

Sieving Machine

Conveying equipment

Bucket Elevator

Mixer

Packaging Machine

E-mail:

sale@xxdahan.com

WhatsApp:

+86 15836198876

Add:

Yanjin county forest park gate to the west 1000 meters north road

Chinese Herb Grinder Machine

Chinese Herb Grinder Machine Pin Grinding Crusher

Pin Grinding Crusher Cyclone pulse vacuum crusher

Cyclone pulse vacuum crusher Spice Crusher

Spice Crusher