Hammer mill

Crushing ratio: 10-50 (single stage can reach 50)

Processing capacity: 200-550 tons/hour

Feed size: ≤550mm

Discharge size: 0-60mm

What is Hammer mill?

Hammer mill is a high-efficiency mining equipment that uses high-speed rotating hammers to impact materials for crushing. It is suitable for medium-hardness and brittle materials (such as limestone, coal gangue, gypsum, etc.). Compared with traditional jaw crushers, hammer design has the advantages of large crushing ratio, high output, simple structure, etc. It is the preferred equipment for building materials, metallurgy, chemical industry and other industries.

Compared with traditional crushing equipment, Hammer mill has the following significant features:

Large crushing ratio: generally up to 10-25, some even up to 50, greatly simplifying the crushing process

High production efficiency: low energy consumption per unit output, large processing capacity

Simple structure: easy operation and maintenance, compact equipment, small footprint

Uniform product particle size: less over-crushing, the product is cubic, and the needle-like content is low

Strong adaptability: can crush medium-hard, brittle and medium-abrasive materials

What types of Hammer mill are there?

PC ordinary Hammer mill: basic model, suitable for small and medium-sized production lines, with a processing capacity of 5-200t/h.

PCZ heavy-duty Hammer mill: for high-hardness materials (such as granite), equipped with reinforced rotors and wear-resistant hammers, the crushing efficiency is increased by 30%.

Reversible Hammer mill: bidirectional rotation design, reducing hammer wear and extending service life.

Why choose a hammer mill?

Efficient and energy-saving: The hammer directly impacts the material, and the energy consumption is 15%-20% lower than that of a jaw crusher.

One machine for multiple uses: By adjusting the gap between the screen plates, the particle size of the material can be controlled (adjustable from 0 to 25 mm).

Easy maintenance: Modular design, it only takes 1-2 hours to replace the hammer and screen plate.

Environmentally friendly and low noise: Enclosed structure + shock-absorbing base, dust and noise meet international standards (such as CE certification)

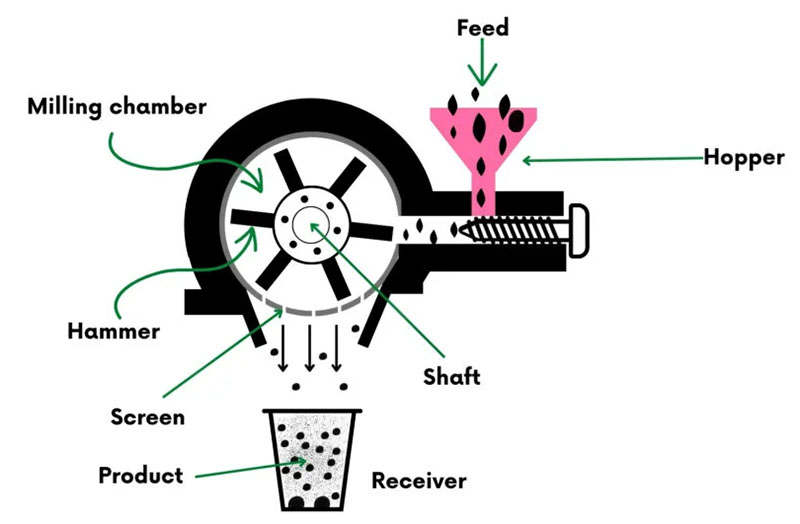

How does hammer mill work?

After the material enters the crushing chamber, the high-speed rotating hammer (speed 800-1500r/min) crushes it through impact, shear and collision. Qualified particles are discharged through the bottom screen plate, and oversized particles continue to be crushed by the hammer for the second time, forming a closed-loop cycle to ensure uniform particle size.

Hammer Mill Parameters

| Model | Feed size (mm) | Processing capacity (t/h) | Motor power (kW) | Weight (t) |

| PC0808 | ≤200 | 15-30 | 55 | 4.8 |

| PCZ1616 | ≤400 | 100-200 | 315 | 22 |

What are the applications of Hammer Mill?

Mining industry: crushing limestone, dolomite, etc. for cement production.

Building materials industry: processing construction waste recycled aggregates, with a recovery rate of ≥90%.

Energy industry: crushing coal and coal gangue to assist thermal power generation.

Chemical industry: processing chemical raw materials such as phosphate ore and pyrite

How to select Hammer Mill?

Material hardness: For high hardness, choose PCZ heavy type; for medium and low hardness, choose PC ordinary type.

Production requirements: For small lines (<50t/h), choose PC0808; for large lines (>200t/h), choose PCZ series.

Environmental protection requirements: Fully enclosed design + dust removal configuration is preferred.

Sugested Products

Related news

Sieving Machine

Conveying equipment

Bucket Elevator

Mixer

Packaging Machine

E-mail:

sale@xxdahan.com

WhatsApp:

+86 15836198876

Add:

Yanjin county forest park gate to the west 1000 meters north road

Chinese Herb Grinder Machine

Chinese Herb Grinder Machine Pin Grinding Crusher

Pin Grinding Crusher Self-dusting pulverizer

Self-dusting pulverizer Spice Crusher

Spice Crusher