Helix conveyor manufacturer

Wednesday July-09 2025 10:10:57

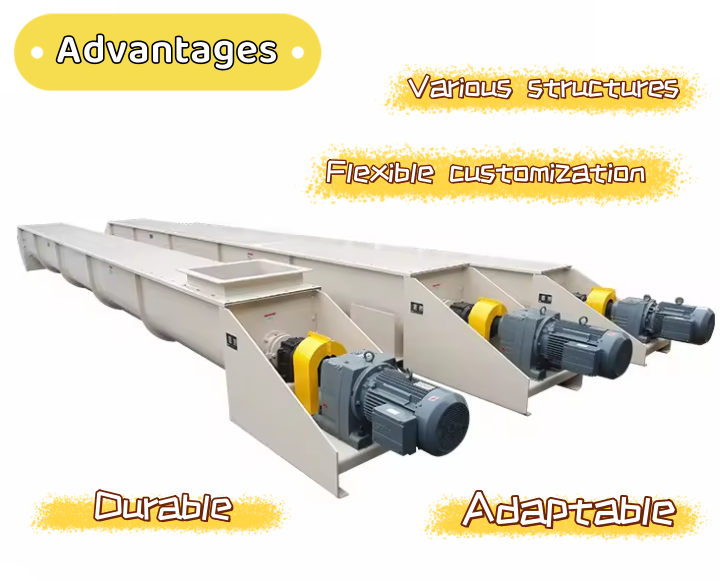

Helix conveyor is a kind of equipment commonly used in material transportation. There are many manufacturers of Helix conveyor, and there are differences in product supply and technical focus. Manufacturers provide a wide range of Helix conveyors, covering a variety of standard models, designed to meet the basic needs of different industries and application scenarios. However, different manufacturers may also differ in material selection, manufacturing process, detail design and product performance parameters. In addition, manufacturers have customization capabilities and can produce customized products according to user needs.

What are the types of Helix conveyors?

Due to its diverse structural characteristics, Helix conveyor shows different adaptability in conveying volume and conveying distance, thus forming a variety of types to meet industrial needs.

Shafted Helix conveyor

Structural features: The spiral blade rotates around a central axis. The blades are in various forms, including solid spirals (continuous solid spiral surface), belt spirals (there is a gap between the blades and the central axis, suitable for sticky or easy-to-wind materials), paddle spirals (with stirring function), etc. The shell can be U-shaped trough type (open or covered) or closed circular tube type.

Conveying capacity: The conveying capacity ranges from a few kilograms to hundreds of tons per hour, which mainly depends on the screw diameter, pitch and speed.

Conveying distance: It is suitable for short to medium distance conveying, and the length of a single machine can usually reach tens of meters. If a longer distance is required, it can be achieved by connecting multiple units in series.

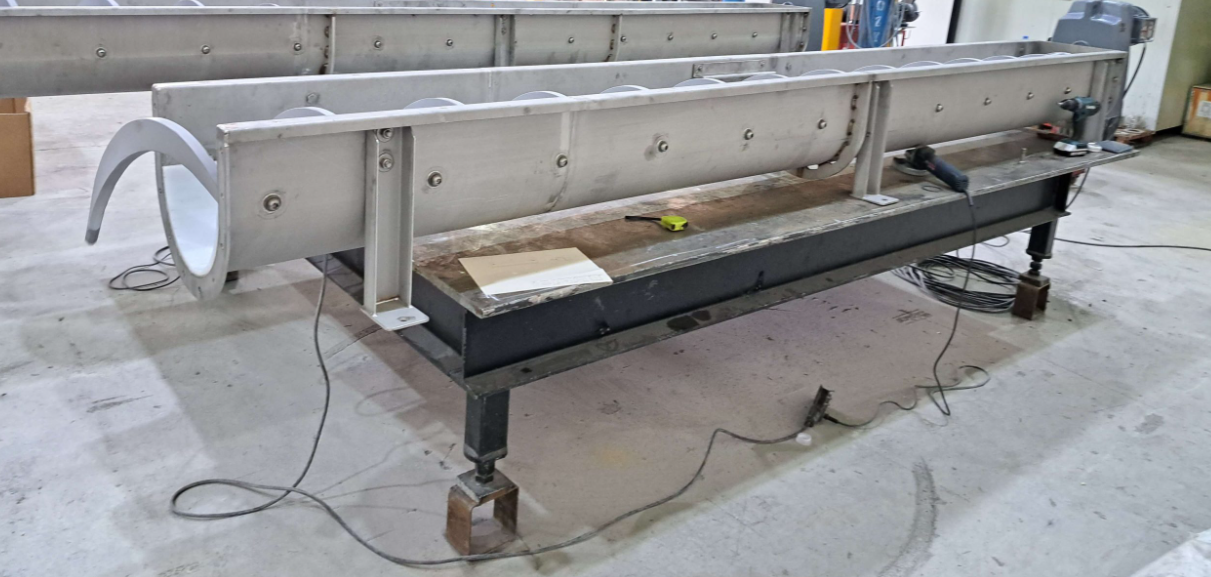

Shaftless Helix conveyor

Structural features: There is no central shaft, and it relies on a thick spiral body to rotate in a U-shaped groove. This design eliminates the obstruction and entanglement of the central shaft to the material, and it is easy to convey sticky, wet, easy to entangle or bulk materials (such as garbage, sludge, and fiber).

Conveying capacity: When handling specific materials, due to the higher filling factor, its effective conveying capacity may be better than that of a shaft conveyor with the same diameter. When handling bulky or entangled materials, its conveying efficiency is higher.

Conveying distance: It is usually suitable for short-distance conveying, or when it needs to adapt to complex paths (such as flexible shaftless conveyors). Due to the deadweight and stability considerations of the shaftless spiral body, the length of a single machine is usually shorter than that of a shaft conveyor.

What are the advantages of Helix conveyor?

Helix conveyor has shown significant advantages in a variety of industrial applications, making it a popular material conveying solution. The main advantages are as follows:

Simple structure and easy maintenance

The design of Helix conveyor is relatively intuitive, mainly consisting of spiral blades, drive devices and casings. This simple structure makes it relatively easy to manufacture, install and maintain on a daily basis. In the event of a failure, diagnosis and replacement of parts are usually not complicated, which helps to reduce downtime.

Flexible layout and small space occupation

Helix conveyor can achieve horizontal, inclined and even vertical conveying, and has strong adaptability. In particular, its compact structure usually occupies less space at the same conveying capacity compared to other conveying equipment (such as belt conveyors). This is a significant advantage for factories or workshops with limited space.

Continuous conveying and stable operation

Through the continuous rotation of the spiral blades, the material can be stably and evenly conveyed from the feed port to the discharge port to achieve continuous operation. This stable conveying feature helps to maintain the balance of material supply in the downstream production line and avoid efficiency fluctuations caused by intermittent operation.

Easy to control, quantitative conveying can be achieved

The conveying volume of the Helix conveyor can be controlled by adjusting the speed of the screw. Combined with devices such as frequency converters, precise material flow control can be achieved, and even quantitative feeding can be achieved. This is very beneficial for process flows that require precise batching or continuous feeding.

Wide range of conveying materials

From fine powders and granules to small pieces of materials, and even some sticky or easily entangled materials (through shaftless Helix conveyors), Helix conveyors can effectively handle them.

What are the applications of Helix conveyors?

As a versatile material handling equipment, Helix conveyor has a wide range of application scenarios. It is mainly used to transport various types of bulk materials between different process points. Helix conveyor can realize horizontal conveying of materials, moving powders, granules or small pieces of materials smoothly from one container or equipment to another. It can also carry out inclined conveying, lifting materials to a certain height to adapt to the height difference of different equipment, or sending materials into high silos. In some special cases, it can even realize vertical conveying, efficiently lifting materials from the ground to a higher position. In addition, Helix conveyor is not just a simple means of transportation. Through specific design, it can also complete some additional process treatments while conveying materials. During the conveying process, it can also mix or stir materials as needed to ensure the uniformity of the materials. If a special jacket is designed, it can also heat or cool the materials while conveying. The jacketed Helix conveyor shell can heat or cool the materials during the conveying process by passing a heat source or a cold source, thereby completing multiple processes in the same device. Its closed structural characteristics make it perform well in scenes that require the environment (such as dust control, pollution prevention) or special protection requirements for materials (such as avoiding moisture and oxidation).

The differentiation between Helix conveyor manufacturers is mainly reflected in the breadth of product types they provide and their non-standard customization capabilities. When choosing a supplier, users should focus on whether the manufacturer can provide specific solutions that meet their own material characteristics, conveying requirements and site conditions. Manufacturers with customization capabilities can provide tailor-made design and manufacturing services based on complex working conditions and special material properties, including the selection of specific materials, adjustment of non-standard dimensions, and integration of specific functions.