Food packaging machine price

Wednesday May-28 2025 17:25:24

Food packaging machine price overview

The price range of food packaging machines is wide, ranging from about $1,000 for entry-level to more than $50,000 for large fully automatic packaging lines, depending on the type of equipment, degree of automation, output and specific model. Small granule packaging machines such as DXDK-40II are suitable for spices, dried fruits, etc., with a price of about $1,500, suitable for low-volume needs; medium-sized powder packaging machines such as DXDF-60C, with weighing and sealing functions, are suitable for milk powder and flour products, with a price of $4,000 to $7,000; large liquid packaging machines such as GZL-8L support multi-row packaging, high output, suitable for large-scale production, and prices of more than $30,000. Configuration differences such as power and voltage will also affect the price.

Detailed quotation table for food packaging machines

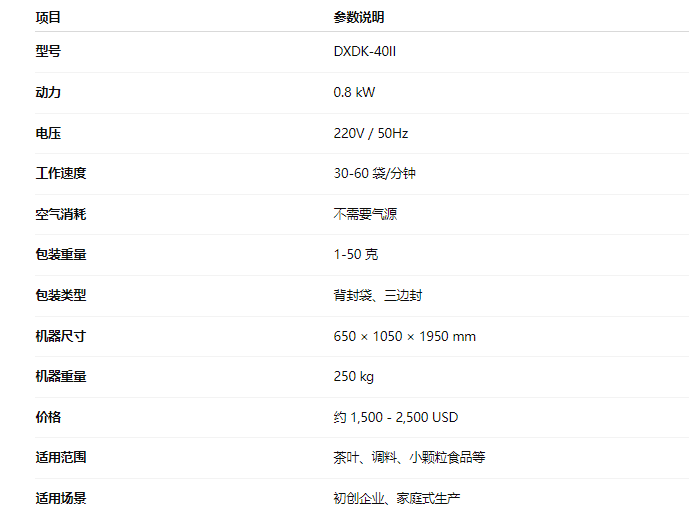

DXDK-40II small granule packaging machine, suitable for small granule foods such as tea and spices, compact structure and simple operation. Power 0.8kW, no air source required, packaging speed 30-60 bags/minute, supports back-seal and three-side-seal bags. Suitable for start-ups and home production. The detailed parameter table is as follows:

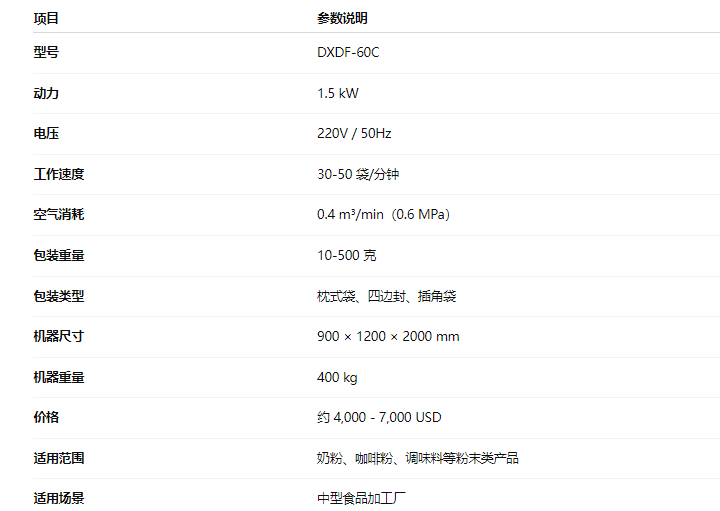

DXDF-60C medium-sized powder packaging machine, suitable for powder products such as milk powder, coffee powder, seasonings, etc., with automatic weighing and sealing functions, packaging speed of 30-50 bags/minute. Supports a variety of bag types such as pillow, four-side seal, and corner bags, suitable for medium-sized food processing companies. The detailed parameter table is as follows:

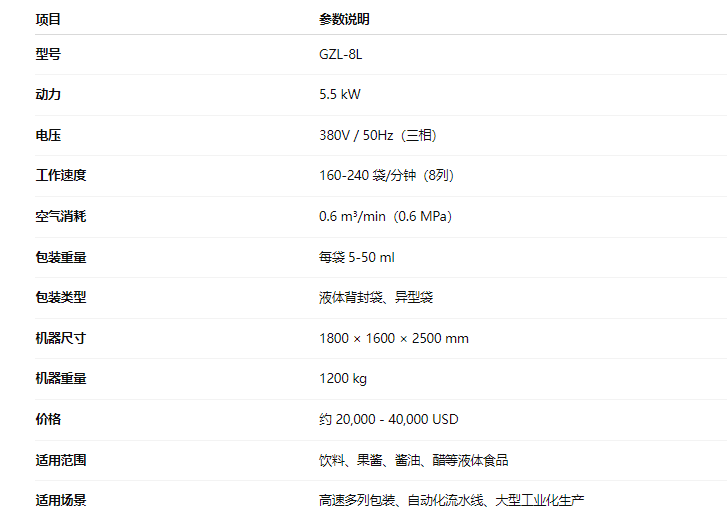

GZL-8L large-scale fully automatic multi-column liquid packaging machine, suitable for liquid products such as beverages, jams, soy sauce, vinegar, etc., supports 8-column high-speed filling, and the packaging speed can reach 160-240 bags/minute. It has a high degree of automation and is suitable for large-scale industrial continuous production. The detailed parameter table is as follows:

How to choose a suitable food packaging machine?

When choosing a food packaging machine, companies should consider the following aspects:

Clear packaging requirements: First, make a preliminary screening based on the product form (liquid, powder, granule), packaging materials, packaging bag type (back seal, pillow, insert, etc.) and weight of each bag to ensure that the selected equipment can meet the basic process requirements.

Calculate the matching degree of output and efficiency: If the daily output is low, you can choose a small packaging machine with compact structure and high cost performance; medium-volume companies need to balance cost and efficiency and choose medium-sized equipment with automatic weighing and packaging functions; and high-volume and large-scale production must use multi-row, high-speed, automated integrated packaging lines.

Evaluate equipment stability and maintenance costs: In addition to the initial purchase price, you also need to consider the equipment life, frequency of parts replacement, operation difficulty and maintenance convenience. Although high-end configurations such as servo systems and PLC intelligent control have high initial investment, the later operation and maintenance costs are low.

Choose reliable manufacturers and service teams: It is recommended to choose manufacturers with production qualifications, rich cases and a complete after-sales system to ensure that equipment commissioning, operation training, after-sales response and other services are in place to avoid affecting normal production due to after-sales problems.

Matching budget with development plan: When purchasing, one should not only consider current demand, but also consider the possibility of future expansion. Select equipment with strong scalability and sufficient reserved interfaces to leave enough space for later system upgrades.

Sugested Products

Related news

Sieving Machine

Conveying equipment

Bucket Elevator

Mixer

Packaging Machine

E-mail:

sale@xxdahan.com

WhatsApp:

+86 15836198876

Add:

Yanjin county forest park gate to the west 1000 meters north road