PVC Plastic High Speed Mixer

PVC plastic high speed mixer is a kind of equipment used for rapid mixing, heating and drying of powdery and granular materials such as PVC resin, filler, stabilizer, etc. It is particularly suitable for the preparation of hard PVC mixed ingredients.

Mixing time: between 5 and 15 minutes

Mixing uniformity: up to 98% or more

Weight: 100 kg-3000 kg

Material: stainless steel, aluminum alloy

Application: raw material pretreatment process in industries such as plastics, rubber, chemicals, masterbatch, etc.

What is PVC plastic high speed mixer

PVC plastic has the characteristics of strong plasticity, adjustable hardness, and good chemical stability, but before processing, PVC resin powder needs to be fully mixed and plasticized with stabilizers, plasticizers, fillers and other additives. PVC plastic high speed mixer is a special equipment designed for this demand.

It generates strong shear force and convection effect through high speed (usually 500-3000rpm), so that the material can be mixed, dispersed and plasticized in a short time.

Classification of PVC plastic high speed mixers

According to the principle of mixing, it can be divided into heating mixing type, non-heating mixing type and cooling mixing type. The heating mixing type uses external heating and the friction heat generated by the materials during the mixing process to mix. The non-heating mixing type uses the heat generated by the friction of the materials during the mixing process. The cooling mixing type is divided into vertical and horizontal types.

Classification by function and working mode

① High-speed hot mixer: This type of mixer uses the high speed rotating blades to generate a large amount of heat by friction between materials, so that the PVC resin and various additives are quickly mixed and reach the preset temperature (usually around 100°C), so that the additives are fully melted and absorbed by the PVC resin to form a uniform dry blend.

Function: Hot mixing is a key step in PVC processing. It ensures the full dispersion and uniformity of various ingredients in the formula, and provides a good foundation for subsequent plasticization.

Application: Widely used in the pre-production treatment of PVC sheets, pipes, profiles, films and other products.

②Vertical cooling mixer: Usually used in conjunction with a high speed hot mixer. After the hot mixing is completed, in order to prevent the material from decomposing and facilitate storage and transportation, the high-temperature mixture needs to be cooled down quickly. The cooling mixer uses a cooling jacket and low-speed stirring to reduce the material temperature to a level suitable for storage and transportation (usually 40-50°C).

Function: Cooling the mixture can avoid the degradation of the material caused by long-term retention at high temperature and make it a free-flowing powder that is easy to handle.

Application: It forms a "hot and cold mixing unit" with a high speed hot mixer, which is the standard configuration of the PVC dry mix production line.

③ Hot and cold mixing unit: It consists of a high speed hot mixer and a vertical cooling mixer in series. The material is first mixed and heated at high speed in the hot mixer, and then automatically unloaded into the cooling mixer for cooling after reaching the set temperature.

Function: Realize the continuous and automated production of PVC dry mixes to ensure mixing quality and production efficiency.

Scope of application of PVC plastic high speed mixer

PVC powder mixing

Preliminary ingredients of PVC products such as pipes, profiles, plates, wires and cables

Mixing of various modified plastics, masterbatches, ABS, PP, PE and other materials

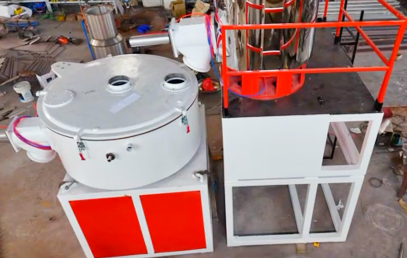

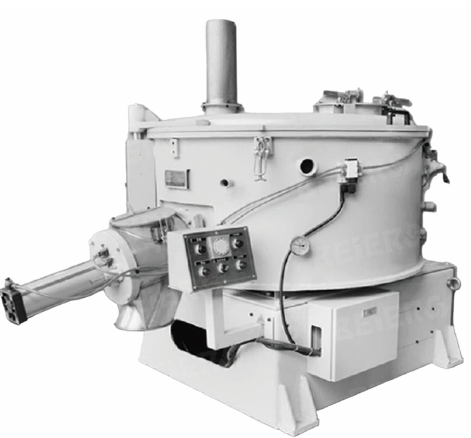

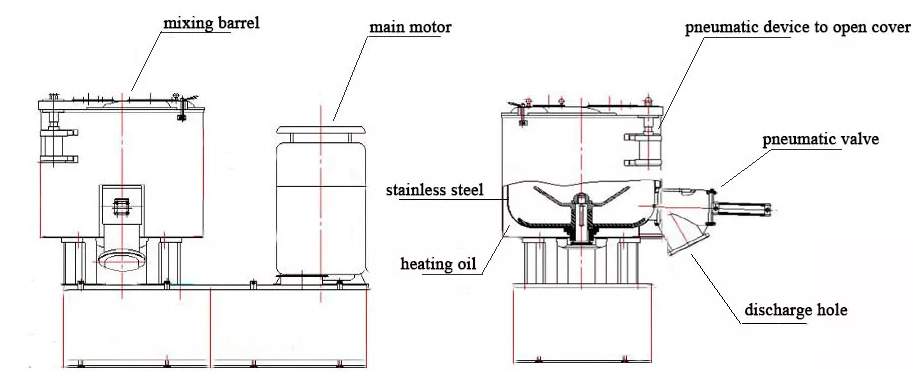

Structural composition of PVC plastic high speed mixer

The structural composition of PVC plastic high speed mixer mainly includes the following key components, which work together to achieve efficient mixing, heating and drying of PVC powder and additives.

Main motor system: vertically mounted asynchronous motors or variable frequency motors are often used to provide high speed rotation power for the mixing blades, which is the core driving part of the whole machine.

Mixing barrel: mostly stainless steel, with polished inner wall to prevent sticking and powder accumulation, which is conducive to full turning and uniform mixing of materials, generally ranging from 100L to 1000L.

Mixing blade system: usually 2~3 layers of blades, divided into main stirring paddles, auxiliary stirring paddles, etc., arranged obliquely. Under high speed rotation, strong shear, centrifugal and convection are formed to quickly mix and heat the materials.

Pot cover and sealing device: Made of stainless steel, can be opened for inspection, with silicone sealing ring or metal compression structure to prevent dust leakage.

Discharge system: usually bottom discharge, with manual, pneumatic or electric control of the discharge valve.

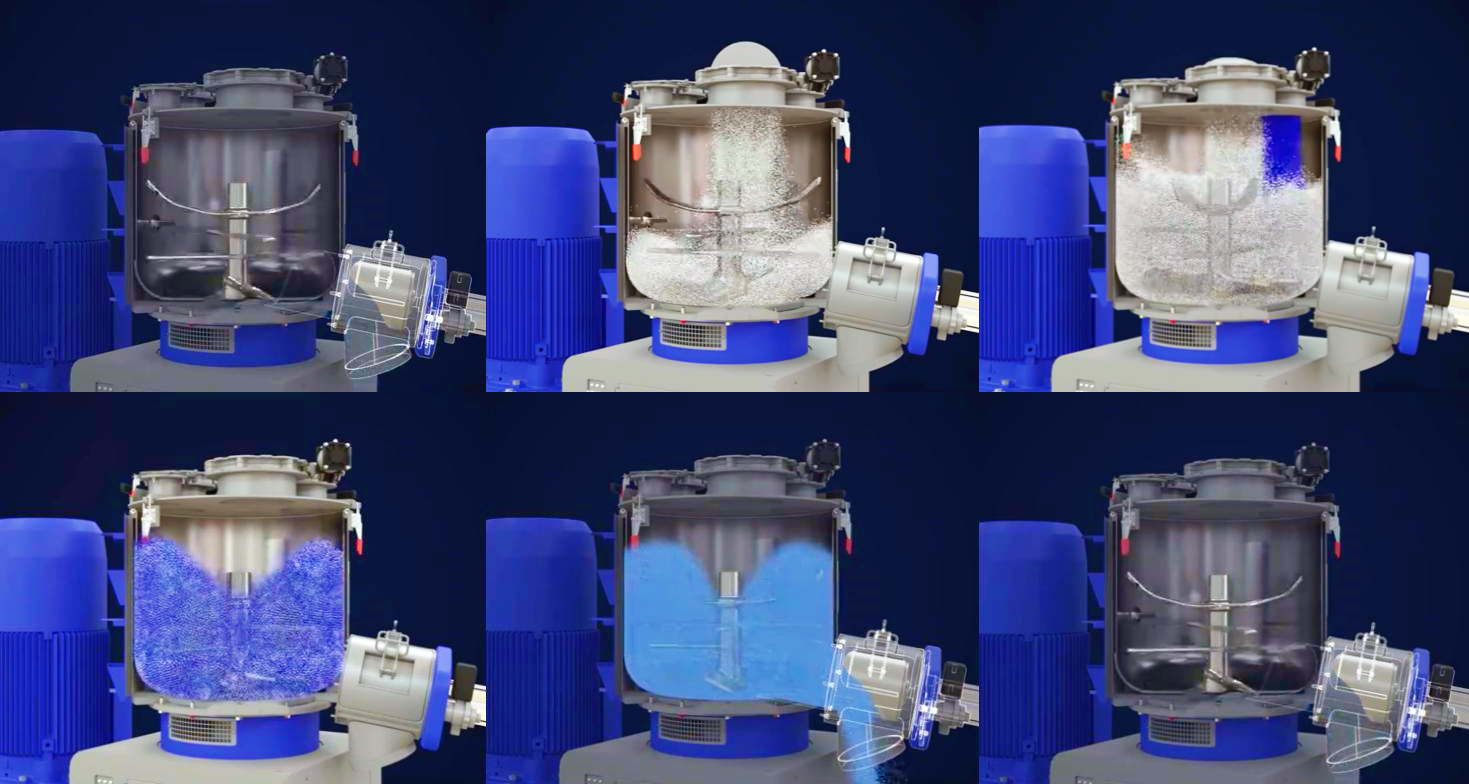

How does the PVC plastic high speed mixer work?

The motor transmits power to the main shaft through the belt wheel and the reduction box, driving the stirring blade installed on the main shaft to rotate at high speed. The blade adopts a special structure (such as inclined blades, anchor blades or multi-layer blades), which generates strong centrifugal force and shear force when rotating, driving the material to do compound movement. When the blade rotates at high speed, the material moves upward along the conical wall of the mixing barrel under the action of centrifugal force, and falls back due to gravity after reaching the upper part of the barrel.

At the same time, the shearing action of the blade causes the material to flow horizontally, and materials of different densities and particle sizes are quickly dispersed and interspersed under the dual action of swirl and shear to achieve uniform mixing. This motion mode makes the material mixing efficiency more than 1 times higher than that of ordinary mixers, especially suitable for the rapid and uniform mixing of multi-component materials such as PVC resin, plasticizer, stabilizer, etc.

Features of PVC plastic high speed mixer

Efficient mixing: The high speed rotating stirring paddle (usually 1000-3000 rpm) ensures that the PVC raw materials and additives are mixed quickly and evenly, improving production efficiency

High speed and strong shear force: The high speed rotation causes strong shear, collision and convection between the PVC powder and the additives, shortening the mixing time (the conventional mixing process only takes 5 to 15 minutes)

Multi-dimensional mixing trajectory: The spiral ribbon type, planetary type and other models use special structures (such as double spiral belt reverse conveying, paddle revolution + rotation) to make the material move in the axial and radial directions at the same time to avoid local agglomeration

Wear resistance and anti-adhesion: The inner wall of the mixing drum and the paddles are often made of stainless steel or wear-resistant coatings (such as tungsten carbide) to resist the friction loss between PVC powder and additives, while reducing material adhesion

Flexible unloading and sealing

The bottom uses a butterfly valve or pneumatic unloading valve, which is quick and residue-free; the explosion-proof model is equipped with a mechanical seal + nitrogen purge system to prevent flammable gas leakage or dust explosion.

Technical parameters of PVC plastic high speed mixer

|

Model |

Volume (L) |

Motor power (kW) |

Paddle speed (rpm) |

Processing capacity (kg/batch) |

|

SHR-100A |

100 |

7.5 |

750/1500 |

30–40 |

|

SHR-200A |

200 |

11 |

650/1300 |

60–80 |

|

SHR-300A |

300 |

22 |

650/1300 |

90–120 |

|

SHR-500A |

500 |

37 |

650/1300 |

150–200 |

|

SHR-1000A |

1000 |

75 |

430/860 |

300–500 |

What can PVC plastic high speed mixer be used for?

Mixing treatment before the production of PVC pipes/profiles/cable materials;

Pre-mixing process of masterbatch to improve pigment dispersion;

Uniform mixing and preheating after adding stabilizers and fillers to avoid stratification in subsequent processing;

Efficient combination of CaCO₃and PVC resin in rigid PVC formulation system.

Price of PVC plastic high speed mixer

The price of PVC plastic high speed mixer varies depending on equipment specifications, functional configuration, brand and other factors, and the approximate price range is between US$400 and US$30,000. Specific as follows:

Small and simple models: Some small PVC plastic high speed mixers have small capacity, relatively simple functions, and relatively cheap prices, usually between US$400 and US$1,500.

Conventional production models: Ordinary specifications of PVC plastic high speed mixers used for daily production, the price is generally between US$1,800 and US$10,000. This type of mixer has a certain capacity and speed, which can meet the production needs of most small and medium-sized enterprises.

Large or high-end models: Large PVC plastic high speed mixers, or models with high-end configurations such as high-precision temperature control, high degree of automation, and special material mixing drums, are more expensive, ranging from US$10,000 to US$30,000, or even higher.